Hey Chris,

a few suggestions for corrections:

Gantry:

A gantry rather means the entire X axis and its two feet running on top of the Y carriages, as a gantry is defined as…

an overhead bridge-like structure supporting equipment such as a crane, signals, or cameras.

– Source: Gantry – Wikipedia

A framework of steel bars resting on side supports to bridge over or around something.

– Source: Gantry – Wiktionary

In the CNC field, there exist types with different arrangements of the axes. One is the gantry-type cnc, which is defined as having the X axis as a bridge that runs on two Y axes, which usually makes necesary two Y motors. The X carriage runs on the X axis and holds the Z assembly.

– Source: Kief, Hans B., Roschiwal, Helmut A., and Schwarz, Karsten: CNC-Handbuch, 31., überarbeitete Auflage 2020, Carl Hanser Verlag, München

Image: The description of a gantry-type CNC machine in a German textbook on CNC machinery (please don’t be confused by the fact they use X for Y and vice-versa, and that they have an additional W axis with which you can lower and higher the entire X axis to accomodate different workpiece heights.)

Bundesarchiv, Bild 102-10412 / CC-BY-SA 3.0, CC BY-SA 3.0 DE, via Wikimedia Commons

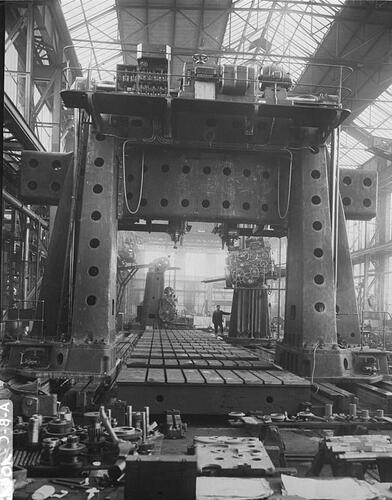

Image:

Gantry milling machine from Schiess Defries

A giant work of German engineering!

A view through a gantry milling machine for machining large workpieces. This giant machine is able to pick up and machine workpieces up to 4.5 m wide and high, as well as 24 m long. This gigantic machine, a product of the Schiess Defries company, is unique in the world.

Date September 1930

Source: Author unknown, Bundesarchiv

G-code:

G-code is plain text, so it is human-readable by definition (in contrast to binary formats), and before the advent of CAD/CAM software, the only way to use a CNC machine was that the CNC programmer had to write g-code as plain text. The amount of a human being able to internally visualize what the numbers mean is comparable to the fact that some humans can look at a sheet of music and can internally “hear” the music.

Workholding

I would not forget to mention the vacuum table. It is the only clamping system that holds your workpiece quite strongly (compared to blue tape and cyanacrylate) and at same time has no holding tools protruding the workpiece surface, so the only method to hold extremely thin workpieces that are too thin for the thickness planer (usually min. 6 mm / ¼") and the method to replace a wide belt sander with a CNC machine. Imagine bringing flat soundboards of musical instruments to desired thickness, which is necessary in tolerances of 0.1 mm, done with the CNC. You don’t really want to tape and glue such large surfaces.