In 2004 when I got laid off and kicked out of Michigan (well, couldn’t find a decent job), I eventually ended up at Toyota (after a several month layover in West Lafayette Indiana). Got to do initial programming on spot weld robots. That was pretty cool. Used to find my way to a maintenance department mill once in awhile, but they always looks sort of disapproving at me, like “what are YOU doing running a mill?”. My boss told me I might have to take machining training in order to use the machines. I told him I’d been running machines longer than Toyota has been building cars in North America. Never heard anything more about it. ![]()

Literally any story would do, honestly. I was so green back then that I didn’t even know what CNC meant. I suspect they told me it was “robotic” to spare themselves the barrage of questions I would have had if they’d told me otherwise. “Oh. So it welds by itself? COOOOOOOL!”

I transferred out to shipping after my arm healed from that aforementioned line incident and became “super awesome will drive circles around you all day” forklift operator for the next decade or so. PSI went out almost as quickly as it arrived in Oxford so I never really figured that being exposed to CNC at that time would have given me an edge. I ended hopping around as a forklift operator forever.

It was pretty late in the game when I took a chance on a job bid for maintaining a single-hit spot welding line, way above my pay grade because, at the time, I didn’t even know what a plc was. Then they started having me work in the tool room for “catch up” work and set me loose on a manual Bridgeport to see what I knew / what I didn’t know about machining. Turns out “not much” but I had youtube. ![]()

Anyway, promotion to Machinist I, a few months of working through making blocks for the CNC operators / die builders down at the other end then up to Machinist II, whereupon I got the honor of manually milling die components that couldn’t be squeezed into daily cnc job runs. THAT was fun! That’s when I realized why a lot of folks head into skilled trades, because grabbing tons of machinery by its haunches and making it dance pretty really makes you feel all warm / fuzzy inside. ![]()

Then off to the other end to watch the CNC operators setup tooling and learn about G Code. All this time, though, I’d been learning 3ds Max but, at the time, never really ever considered how, one day, I might actually be able to blend the two industries. Of course, those CNCs were actual CNCs with atc, actual enclosures (it’s on my to-do list) and way WAY more expensive tooling.

It’s neat to look back on it all, though. From watching a “robot” weld parts with the awe and enthusiasm of a toddler to owning and operating a tiny desktop CNC… what a long, crazy, circular journey. ![]()

Wait, so we’re all from Michigan here? Eh, it makes sense. We used to be the go-to for manufacturing divisions. I hate outsourcing!

I guess I’ll extend a hearty ope since we’re all Midwest. ![]()

I’m all the up here in Alberta! It was oil and gas that got me into NDT work. After taking business marketing I figured I’d into NDT and weld inspection and leave tv sales and Pepsi merchandising in the past.

Once I got into a machine shop full time I was finally able to get a proper wood shop set up(follow your dreams right?). My first cnc was some cheap no name desktop machine. That thing only lasted me 6 months before the onefinity which has only been running for roughly a year now. So I’m brand new in the cnc world.

I consider the high-point of my career to be in the mid 90’s working for Novi Industries, which was one of the automotive equipment build shops owned by PICO, which was a large conglomerate of design & build shops based in Southfield. One of their design shops was offering free AutoCAD classes, so I jumped in with a vengeance and soon became AutoCAD certified, and moved into tool design. Those were my good old days, but I still miss just running a manual Bridgeport.

+1, family moved out of the Jackson area when I was 10.

Walking away from it all. After decades of being bounced around from tier 2 to tier 2 and experiencing way WAY too many indefinite layoffs as shops folded and head to Shanghai, I threw in the towel. Some of the shops you just have no choice but to fall in love with and, one day, they just up and close.

Well, that’s a bit cynical. I think my high point was being plucked from general labor / machine operator to that tool room. I don’t know what they saw in me but I’m glad they saw it and gave me a shot. That was one of those shops you had no choice but to fall in love with. Good people running the show.

That, I didn’t do and it wasn’t offered. I was already about 10 or 15 years into 3ds Max so had effectively mastered the bulk of it for 3d content creation. That’s like operating a manual mill, though. All the splines, boolean operations and extrusion functions are there but I don’t think they’re nearly as refined as they are in AutoCAD. For visualization and concept, it’s been amazing but I probably would be well behind the curve if using it for fast-paced production.

Amazing! I’m originally from the Thumb but ended up fairly early in and around Flint. Buick City was still a thing, though briefly. I remember their sort of “last call” near the end when they were just looking to hire temps that would hit layoff at 89 days. Then they were gone, Flint folded up and we were fortunate enough to escape before things got real bad.

It does make a lot of sense that many of us would be from around the same region. You sort of grow a thirst for fabrication when all you know is fabrication.

All day, every day!

Meh, close enough! ![]()

Seriously, I grew up in a State whose closest neighbor was Canada. I even took 4 solid years of French because my ignorant, younger self thought that ALL Canadians spoke French and that I would eventually grow up to be crossing the Blue Water for a living. I have no idea what I was thinking but, after having bounced around most of the US, I can honestly say that I wish I had taken Spanish instead for how well French has served me over the years. ![]()

Ah, Flint! ![]() Was born there, moved away, then ended up back in that area mostly in the Fenton area, doing the commute to Novi. If you’re on FB, you might want to check out the Memories of Flint group. Always interesting pics being posted. Redirecting...

Was born there, moved away, then ended up back in that area mostly in the Fenton area, doing the commute to Novi. If you’re on FB, you might want to check out the Memories of Flint group. Always interesting pics being posted. Redirecting...

Also did some time in Birch Run, that was fun.

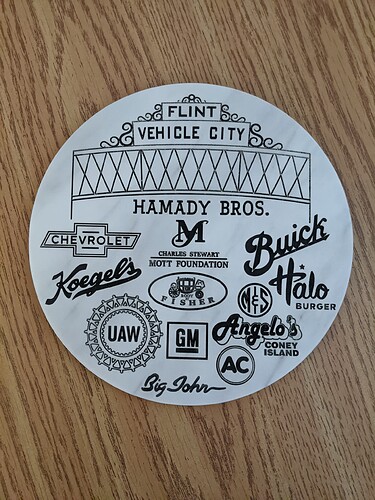

BTW @BJS3D here’s a little project I did that you might find interesting.

I love it! It’s a tragedy of epic proportions that it’s more of a tribute to Flint’s excess in loss. It definitely commemorates the former greatness of what once was a thriving metropolis.

I was kind of all over the map, headquartered out of Flint / Burton and working either to the East toward Imlay City or South toward Oxford, Pontiac and Brighton. Probably passed you up many, many times along US 23.

Once Ford went to Mexico, GM went to Shanghai and Chrysler succumbed to being ran into the ground by Chrysler, we just had to recognize that manufacturing for Michigan was on its last breath. Staying too long meant getting stuck like a lot of poor folks in Flint and Detroit. And I should admit that there would be no adapting to the changing times for me. I love metal fab. It was too late in the game to strive to become a lawyer and I’m just not shady enough to sell used cars.

I do miss it up there, though. Some of the most beautiful shoreline I’ve ever seen, including Florida, Oregon and California. And don’t even get me started on the U.P. I could happily get lost anywhere up there.

I wouldn’t doubt that for a second! Put lots of miles on US 23.

I specifically recall when I heard that GM was opening another production plant in Mexico, I was sitting in my car at lunchtime listening to the radio (1982 maybe). I literally felt sick to my stomach, it was like I could foresee the ultimate conclusion. One of the first nails in the coffin of rust-belt manufacturing.

I do dearly miss Michigan, but the heat & low humidity has been very good for us here in Phoenix. Better for the Onefinity, too! ![]()

I should apologize @CMAC & others for derailing the original conversation off a cliff & into a dry riverbed. But it’s been incredibly interesting. Hopefully we did provide some useful feedback regarding remote desktop.

No need to apologize!

Oh, you’re definitely a bit ahead of me. I was rocking kindergarten back then. ![]()

A decade later, though, all I can say regarding the job market and such is “wow”. There was way too much competition and nowhere near enough decent jobs to go around. Mayhem may be a better word.

We just got back from Redding, California last October. I’m just glad to be back in the Midwest. I can’t do that level of heat, man. 120 degree days for months on end, not a drop of rain for 9 months then 3 months solid of it. Not many storms, though. I missed the storms. Get back here to the Midwest a few days prior to a really nice storm and I was all like, “Oh boy! We’re gonna get us a tornada!!!”, like it was Christmas and that’s PRECISELY what I asked Santa for! ![]()

And wrinkles! I’m 47 years old this year but I pruned-up so quickly and efficiently, I sent raisins into existential crises. They didn’t stand a chance against the unremarkable plainness of my complexion!

Quite the deviation from context but I’ve been grateful for it. When you’re born and raised in a place then life gets in the way and you end up “wherever”, it’s like continuity is broken. Connections to the past are lost. I’ve enjoyed this more than I can reasonably say without coming across as overly sentimental.

In context, though, I stumbled upon AlphaCAM. At face-value, it looks promising and one of only two solutions that came up for the iPad on SourceForge, the other being Fusion 360 as previously mentioned.

Oh, me too my friend! Love talking to old ‘neighbors’. The closest I’ve felt to falling in love with another geographic area is when we lived in Kentucky for 6 years while I worked for Toyota. Very easy place to feel at home. But alas, that wasn’t meant to last.

Let me just say this about that: while I have used TeamViewer and Chrome desktop share, I should qualify that by saying it was on a laptop where I could still effectively use a mouse. I do have my doubts & reservations about using an iPad or similar with a touch pen. With some of the stuff I do, I need to be able to zoom way in & select small geometry effectively. I’ve not seen an iPad touch pen, so I don’t know if it’s precision enough to use in that manner.

So I clicked on the AlphaCAM link you provided, and was memory-jolted by the Hexagon icon. I see that it is affiliated with Hexagon Metrology. They have an office in Novi, and they used to come into the shop I worked at to do laser measurements on the robotic weld lines we built.

BTW, totally more off-topic. As I work from home, I listen to CARS 108 on Alexa. WRIF doesn’t offer much in terms of recognition or enjoyment to me anymore, but CARS 108 has been almost like I never left the Flint area.

I looked into alphacam a while back and their system requirements specify windows only. But you’re correct that sourceforge states it works on ipads. I’ll fire off an email to them to find out.

Overall its seeming like remote desktop may be my only option for this until the software is created. If that ever happens. lol

As a tech geek, I’m thoroughly biased so you’ll have to take what I’m about to suggest with a grain of salt:

It’s not about what you can and can’t do, it’s about Apple. More specifically, it’s Apple’s operating system that’s limiting your abilities. To punctuate that point, I had a basic Windows-based Lenovo tablet a few years ago onto which I installed 3ds Max… as a sort of “can I do this?” experiment. What I found is that, not only could I, I could also render a decent scene. With a tablet. It was fairly slow-going due to the hilariously inadequate system resources but it just did what I told it to do.

Microsoft Surface Pro + Fusion 360 for the inevitable win, perhaps, but the apprehension to abandon Apple would probably be the same for me to abandon 3ds Max: proficiency. It’s not so simple to just start over with a completely different UI and toolset but, if the equipment you’re working with fights you every step of the way to achieve an objective while other equipment exists that facilitates achieving that objective as-is, logic might suggest it’s time to consider a change.

I do recognize that Apple has seemingly transitioned away from its former “Intel Inside” foundation so it may just be that it’s repositioning itself to inspire more developer support. The specs of the iPad Pro M1 are of such high caliber that I would opt for that over its rival, the Surface Pro 8, and just wipe the internals and install Windows. BLASPHEMY, yes, but it’s best of both worlds: excellent specs coupled with an OS that is highly supported.

I’m not a purist, though. I’m not going to say scrap Apple just because it’s Apple. I think the OS is pure trash but Apple technology has become a seriously formidable player alongside Intel. Windows on a Macbook Pro? Yes. I’m THAT guy. ![]()

Also Linux on a Chromebook and on a ThinkPad, just so you know it’s not all about hating on Apple. ![]()

totally agree!

I guess its hard to tell based on the topic here and what I’m looking for, but I am a PC guy all the way! (other than this 1 ipad that was a clearance sale ![]() ). I honestly felt a bit strange buying it but the Shapr3D app is amazing. Being able create my projects in 3D and getting the 2D drawings with all dimensions for each individual piece was well worth it. Plus having a dust proof device in a wood shop is very nice with the added benefit being able to design anywhere I go.

). I honestly felt a bit strange buying it but the Shapr3D app is amazing. Being able create my projects in 3D and getting the 2D drawings with all dimensions for each individual piece was well worth it. Plus having a dust proof device in a wood shop is very nice with the added benefit being able to design anywhere I go.

I almost went for a surface device but the price was 4x as much. At that time I was only looking for the ability to design and create drawings/cut lists on the go. The ipad and apple pencil was the way to go for that.

I have more then enough computing power in the house between the 3 gaming rigs, VR setup, and racing simulator. Obviously VR and racing sims don’t help. haha… But the rest can run everything I need as long as I keep it out of the dusty shop.

My entire woodshop including CNC and some cool tunes to work to can be run from a single ipad. The CAM software is the only missing piece at the moment.

The idea of remote desktop is something I will definitely try. It seems like a great idea… I just happen to have the ipad already so I figured I’d start with that before spending more cash.

Shhh. Don’t let my workstation hear all of this. It doesn’t know it’s not supposed to be this abused. ![]()

I build a workstation about once every 10 years, the one just retired was from 2010 assembled with far too many Chinese components (I’ve had some issues) but served me fairly well with 8-core AMD CPU, 12 GB Ram and a decent Nvidia GPU. It was aging, though, so had to be relegated to the dust bin of server servitude to replace a severely aging Windows XP server (from really early 2000’s).

This one should last well into the 2030’s, assuming no major breakthroughs in quantum computing (tough to call at this point). This is 24-core AMD CPU, 128 GB Ram and an AMD GPU taking advantage of PCIe 5.0’s massive bandwidth capacity. And it’s living at ground-zero of the CNC’s affinity for making huge messes. ![]()

Nah, that’s fair enough. Personally, I don’t a grand to throw like that so I’m pretty much just throwing ideas.

I wanted to circle back to this. How did you come from a mechanical/machining background and end up running 3ds max? I had heard of it many years ago, but I was under the impression it was used more for organic graphics creation, presentations, animation, etc. Back around the time that came out (if memory serves), we were burdened with a transitional program called AutoCAD ‘Mechanical Desktop’ which was handed up to us from the 7th circle of hell for anyone that dared to want to do mechanical design in 3D prior to the Inventor / Solid Works. But coming from the mechanical design realm, 3D Studio was in our vocabulary.

A life-long blood lust for artistic expression. It started with crayons, drawing and painting, transitioned through Adobe Photoshop / Corel Photo-Paint and eventually landed on 3d graphic design. I also have always loved working with my hands and creating.

I will say that it’s not easy to use 3ds Max for mechanical design. For simple things, you can just create spline profiles but, even then, you’re got to manually create an entire blueprint one aspect at a time. For the more complicated designs, you’ve pretty much got to create the entire model and pull cross-sections out as splines for representation of profiles, again setting everything manually to print a standard blueprint.

That’s what I love most about a lot of the CAM programs and cnc’s. They’re able to work with many different file formats. Vcarve Desktop, for instance, allows for the direct import of .STL files that I export out directly from 3ds Max, either as full-on 3d models or as splines (more as you’d expect if working with .DWG files). And no need to process blueprints since the workflow is pretty much from 3d space through toolpath creation and out to running jobs.

Best of all, since investing in Vcarve, I no longer have to fork asset creation. The 3d printer slicer and the CAM software can both utilize the same exact .STL exports.

I only toyed with it in high school. At the time, I was taking metal shop but that entailed sheet metal fabrication, welding, forging and casting, none of which required learning of CAD. So I also took advertising design. That’s the doorway into learning Adobe Photoshop.