Updated 7/17/25

Applies to both regular and braking motors.

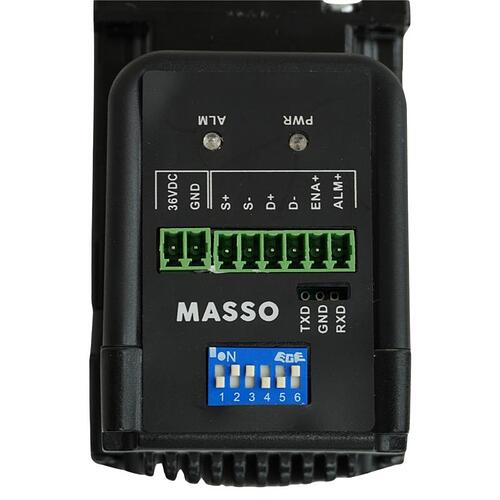

Wiring diagram

- 36VDC = Positive Power - Red Wire

- GND = Ground Power - Black Wire

- S+ = Step Positive - Yellow Wire

- S- = Step Negative - Orange Wire

- D+ = Direction Positive - Gray Wire

- D- = Direction Negative - Black Wire

- ENA+ = Enable - Green Wire

- ALM+ = Alarm - Purple Wire

Dip Switch Location:

Dip switches are the white switches numbered 1-6 in the blue portion of the motor.

Dip Switch 1 is Down/Off

Dip Switch 2 is On/Up

Dip Switch 3 is On/Up

Dip Switch 4 is Down/Off

Dip Switch 5 is Down/Off

Dip Switch 6 is On/Up

Switch 1-4 adjust resolution.

Switch 5 is the rising or falling of the clock edge of the step signal.

Switch 6 is motor direction.

Replacing Motor Video:

Tech Specs:

MASSO 36V

Closed-Loop Stepper Motor Specifications

Frame size: NEMA #23

Shaft: 8mm (.315")

Input Voltage: 36V DC

Output Current: 4.5A 20 KHz PWM

Pulses/Revolution: 800

Maximum Torque: 1.2 Nm (Newton meters)

12.236 kg/cm (kilogram centimeter)

169.934 oz/in (ounce inch)

10.62 in/lb (inch pound)

Torque Information

Stepper motors provide high torque at low RPM but as

the RPM increases the available torque reduces. The

below graph can be used for machine feed rate and torque

calculations.

Status LED & Alarms

The motors provide two visual indications of motor status.

A Green LED indicates that the motor is powered.

A Red LED indicates that the motor is in an alarm state.

Alarms can be caused by any of the below reasons:

• The enable signal of 5v to 24v is not received by the

motor.

• The motor received STEP signals that have acceleration

or top RPM higher than the motor can support. This

will also be affected by how much load is on the motor.

• The power applied to the motor is less or more than

the motor’s specifications.

• The current required to work under load is not enough.

• The motor is not able to complete requested rotation

due to external mechanical issues such as the machine

axis hitting something or getting stuck.