Modeling tab with different layers zero planes and clippings, you won’t get rounded text like aspire gives you but you can get flat text.

Clock for my cousin’s baby. The pattern was made by my grandpa for an applique on our kid’s toy box. He passed years ago and many of my cousins don’t have much made by him. So I photoshopped an image of the applique and it captured even his false cut. From this image I made a clock for my cousin’s nursery that captures his character and his band saw cuts. I was also able to “sign” it with his name from a photo of his signature.

Hi, new to cnc and first time posting. I have the onefinity woodworker, brought it cause I’m building my dream kitchen and that seemed like a good enough excuse ![]()

I also have a farm and am mostly self sufficient. I needed a new cheese press as my previous one in my old kitchen just used dumbell weights, which on occasion got dropped on the benchtop or floor ![]() . I didn’t want to use that in the new kitchen with solid oak floor, so a new design was needed. I’ve now made 2 cheeses with it and I’m stoked! Even more so cause I did it all on my onefinity.

. I didn’t want to use that in the new kitchen with solid oak floor, so a new design was needed. I’ve now made 2 cheeses with it and I’m stoked! Even more so cause I did it all on my onefinity.

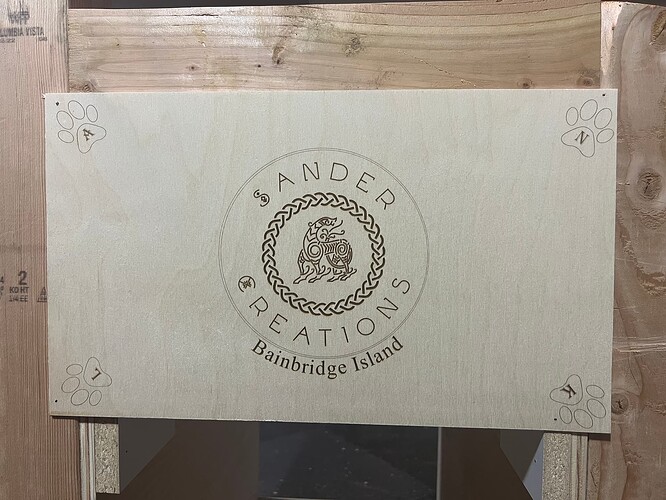

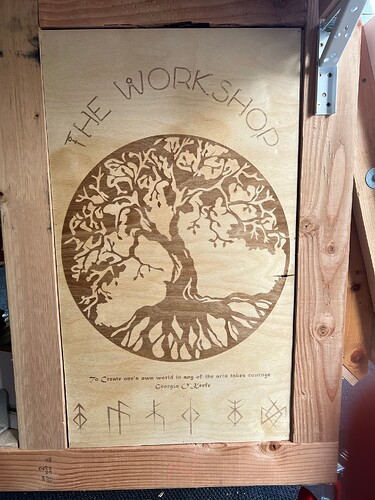

I am continually impressed with aspects of this machine and the 14w laser. When things work out, they look so freaking great. I am building a new workbench for my table saw with a router table on the side. I needed a covering for the router compartment and I couldn’t very well just leave it blank now could I? It’s a very simple project but I love the way it looks.

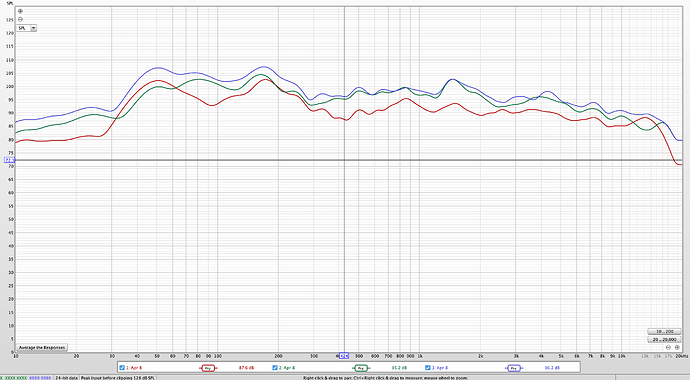

Nice looking towers! Is this your own design or from purchased plans. If they’re your own design, what software did you use to create the curved driver front plane?

I assume the sub is chambered to separate it from the tweeter and mid range, right ?

I did the design using OnShape and Fusion 360. Basically achieved the curve with a loft and guides.

It’s actually a woofer that I’ve crossed pretty low to minimize issues caused by the distance from the midrange and tweeter. It isn’t seperated internally from them. I was worried about issues caused by the distance, but none have been apparent in listening or measurements.

I’ll have to check out OnShape. Thanks for the tip!

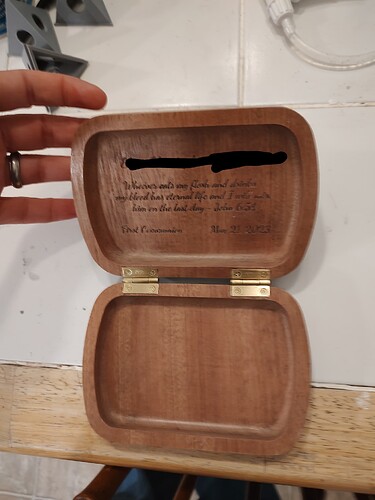

Box for my Godson’s First Communion. Made of Sapele, which continues to impress me in the quality of it’s carvings.

What is the height and largest diameter of this lamp. Love the proportions of it.

Hi Billy, height is 19.75, diameter is 8.25.

The analog dial indicator I have didn’t come with any type of case.

Half an hour or so in Fusion 360 and about 25 minutes in the machine with a scrap 2x4 block, and I have something good enough to keep it from getting knocked around.

Now to make a nice drawer tray for two dial indicators and three calipers, using something other than scraps. ![]()

Proof that your 1F is more than a useful tool for the shop!

Second train table is ready for assembly. Going to flat pack this one for a trip next weekend. Will assemble on site.

This one is for my aunt’s grandson.

Really nice carves. Please tell us more about them.

Pony

Thanks! I found the 3d models on https://www.ameede.net/ small pieces are 4" with the large round 8".

The large piece takes about the same as 4 smaller. around 1.5 hrs for roughing with 1/4" EM upcut 80 IPM & finish takes 9.5 hrs with a tapered ball nose 4% stepover at 50 IPM.

Made some drawer fronts for my new work bench. The 1F helped me with the inlays. I also used it to cut all of the T-Tracks in the melamine. Drawer fronts are cherry with cocobolo inlays. I also used the laser to make a covers for the back of the drawers and one side of the router table section.

Original plans are from Paoson Woodworking.