Hey Tom,

not if the toolpath contains a Z position in absolute distance mode. In this case, if the previous coordinate system offset (workpiece Z zero) is still in effect, the machine will mill at the height where it milled the previous pass, which will be milling air. It’s the manually setting Z zero/probing Z on workpiece top/G92 Z0 that makes that it will mill the next pass at a lower height than before.

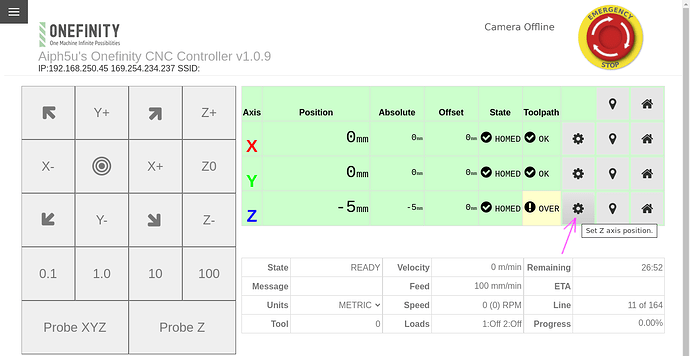

EDIT: I think you mean entering into the Z axis position value (small gear wheel button). Yes, this would change the Z workpiece zero like G92 does. This will work if you have a Z position command in the toolpath, and it will take the new Z workpiece zero when moving to the milling height. Otherwise it will have no effect, because setting a different workpiece zero value does not trigger a motion. Only subsequent motion commands for the corresponding axis will.

By the way, lowering Z means entering a smaller value. Z=19 is lower than Z=20 and Z=−51 is lower than Z=−50.

– Source: here