Guy77

July 10, 2025, 8:15pm

1

I have been using my X35 CNC for the last 3 yrs to cut hard wood and I am making the move to 6061 Aluminum. I am newbie with metal cutting.

I need to cut several 19 in by 2.5 in rectangles with 9 holes that are 3/8 in each inside the rectangle. These are faceplates for amplifiers I build.

I will be cutting from 16 AWG aluminum (.063in) flat sheets that are 24in x 12in

I am trying to decide between using a 1/16 in or 1/8 in endmill?

Both of the ones I have are Z Rn coated. I also have some Helical brand 1/8 in 2 flute bits made for cutting aluminum.

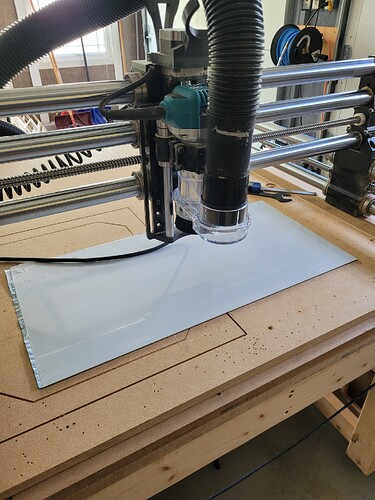

I will use the tape and super glue method for hold down since I have good results in the past with other thin materials.

I am also wondering if I should stick to a .01 in feed rate and around 20ipm feed?

Thanks everyone!

1 Like

HardtailSr

July 10, 2025, 9:01pm

2

I have used my former bb journeyman to mill aluminum and find the single or zero flute bit works well. A bit of lube, like a solution of rubbing alcohol and a tiny bit of dish soap will help keep the aluminum from gumming up on the bit

1 Like

Guy77

July 10, 2025, 9:12pm

3

Thank you Robert. I will mix that into a spray bottle.

Cheers

ChrisM

July 10, 2025, 9:16pm

4

Just a suggestion.

2 Likes

HardtailSr

July 10, 2025, 10:28pm

5

i was not drilling i was milling so i used 1/4 inch zero flute.

2 Likes