I just started surfacing my waste board and it says it’ll take 4 hours. I think that may be too long? I’m shaving off .05 at 80ipm 12000 rpm. Can you let me know how long it took for your board and what your settings were? Thank you all!

Change your feed rate to 180ipm 12000rpm and doc to .25 It will go faster.

- what program are you using, and can you change your speeds in CAM?

- what size bit are you using?

- you can stop the process at any time and adjust to something that work for you…

- there is no right or wrong… just test!

I used easel to create the file I’m using a 1” diameter bit. I thought once a program was running nothing could be changed unless you edit the gcode. Am I wrong? I know I can dial up the router but as far as adjusting feed, I didn’t know that was possible.

You’re saying to go deeper and that’ll help get it done more quickly? I get the increase of ipm but not sure how going deeper will help speed things up…:

You’re not the only one. If you’re only looking to shave off .05" (which may be enough) and your DOC is already more than that, defining the tool with a larger DOC won’t change how it machines as it will only make 1 pass. It’s only if you have a low DOC and a deep cut that exceeds the DOC so multiple passes would be required that an increase in DOC may decrease the overall job time as it’s not going to need as many passes.

I don’t get the deeper DOC comment either.

You will need to go back into your CAM software and adjust you IPM and then re-generate the g-code. I would suggest doing passes of 0.25-0.5 mm (0.01-0.02") NOT 0.25".

The reason to increase the doc to .25 (which is what the 1" 1/4 shank is rated to cut at) is so it only takes one or two passes. The waste board is just that so taking a little more off the first time to insure everything is flat is fast easy way to go. I have changed out my waste board 2 times now and this has been the fastest way to get it done. To me saving a little bit of surface was not worth the time it took to barely skim the surface and do it that way. I think because I cut down to the wasteboard a lot in clearance paths I am constantly resurfacing it for new projects. They only last about 3 months before I have to change them.

Thank you @JDog I wonder if mine was saying 4 hours because i set it to take off .05 on the first pass…biting off more than it can chew perhaps… big ol oops… I had it set to imperial. that;s probably the BIGGEST issue.

No I am saying it will cut .25" imperial. .05" is less than 1/16 of material. The surfacing bit can cut 1/4 inch of material in one pass. Making a thicker cut will shorten the time.

ok got it, makes sense!

The table itself should be reasonably level to start with, then after installing your wasteboard you would only need to skim it lightly to obtain a flat surface. If you are using MDF then it is pretty flat when you buy it so wouldn’t need much to get it perfectly flat.

That’s been my experience. I don’t think I’ve had to surface a wasteboard more than 0.10" max when using MDF as the wasteboard material. I do “onion skin” my cuts in normal use but that doesn’t chew up the wasteboard so badly that it needs a deeper pass. With t-track embedded in the wasteboard there isn’t enough room to take off qtr inches at a time ![]()

@JimHatch I like the term onion skin. What depth would you say that is going to be is it the .10 you referenced?

Yep. I have used 0.05" but any variability in the material thickness and it’s not through-cutting and you’ll be breaking out another tool.

Pretty new to this but I’m guessing your cut time is so long because you have a small stepover. For surfacing should be at least 40% (0.4 inches for a 1 inch diameter bit). With a slower feed rate surfacing took me about 30 minutes (approx 32 x 32 wasteboard)… Hope this helps!

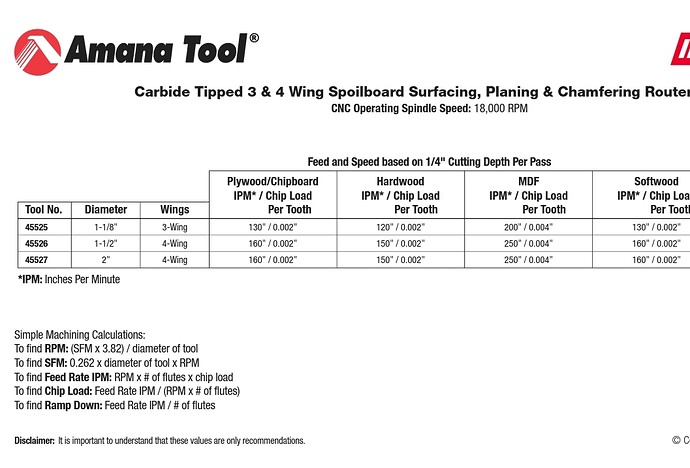

How are you guys getting that depth of cut? I use this bit, run it at 120ipm 18000rpm only .01doc

I cannot find anything on depth of cut for this.

I do 60% step over for surfacing

Theoretically you can cut as deep as your cutting edges, but in practice that rarely works out cleanly.

With a surfacing bit I’d not go deeper than 1/4" simply because my intuition says not to (sorry that’s not very helpful), however I have no problem running 3/4"+ deep with a 1/4" end mill.

As long as your chipload is appropriate based on feeds and speeds depth of cut is up to you!