We’ll I’ve tried everything. I’ve re set-up the machine twice and put in all new fastening screws. But it still won’t mill a perfectly square corner. I’d say it mills a line out of square by about one millimeter in 16 inches. All of the bolt have been checked and everything is very tight. What’s next?

Hey David,

how did you check for rectangularity? I find using a bar gauge for a first check for identical diagonals is very useful. When you adjust the rails then, it is good to loosen the eight bolts that attach the X axis to the two Y sliders a bit, then do the squaring of the rails with the bar gauge, and then tighten the X axis bolts again.

By the way, when mounting the Onefinity CNC to a table top, I always suggest not to use the wood screws that come with it, but bolts instead, or better bolts in sleeves (e.g. brass) with bolts in it. Their diameter would need to be exactly 8 mm:

Thank you, it seems that no matter what I did I could not get the diagonals to match. I’ll try it your way once again though. And maybe I’ll change to bolts although my surface is a torsion box that is 3” thick. My machine is the X32 with the X50 x rail.

Hey David,

to get the diagonals to match, you only need to loosen two adjacent feet of the machine (let’s say, the two front feet), and to shift them between right and left (with X axis slid to front, and its bolts loosened additionally)

Further reading

The so-to-speak “official” thread in this forum about rectangularity of the machine is “Is your router frame a parallelogram? Mine was! ”

[quote=“Aiph5u, post:2, topic:22570”]

would

[/quote

BTW, I have the original Onefinity controller.

Thanks for your help. I’ve had the machine for a few years now but somehow it got out of whack. It was very square right out of the box but I store mine in a vertical position with stop blocks on the x rail but one of them got knocked out and I think it torqued something out of square. Now it’s just been a pain to get it back into square. The diagonals are still about 3/16” different measured at the black corner blocks. I’ll try measuring where the tubes are connected.

Hey David,

yes, I can imagine that. It’s always not helpful when gravity is your enemy ![]()

Just to let everyone know, I’ve finally succeeded in getting everything all squared up and BOLTED down securely. I appreciate all of your help. It just took two more hands attached to a friend of mine and now she’s up and running once again!

Thanks everyone!

Capn Dave

Yep. I used M8 bolts. They fit the holes in the 1F foot precisely.

Ok, I have read this thread several times and I cannot figure out why my cuts are out of square after trying most of these methods. I would really appreciate some help.

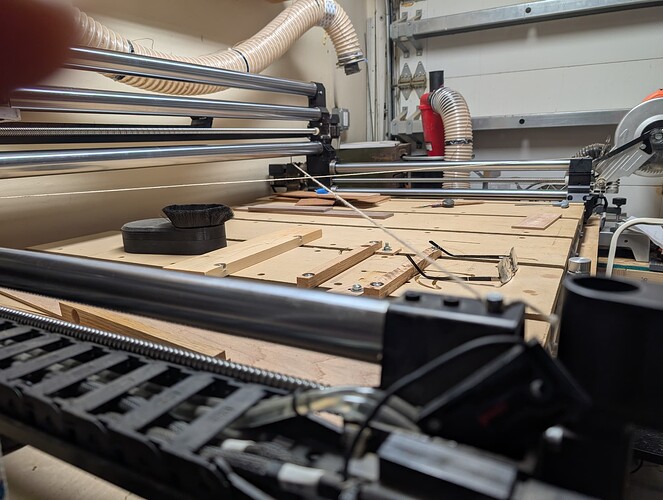

I posted photos below so folks can visualize what I am describing. I have an Elite Journeyman and have been using it for going on two years. I do not know when the machine got out of square, but it is possible that it has always been that way because I cut out mostly small parts that are not square.

I found recently when I was cutting squares and engraving some rectangles that there was a problem. If you look at the last image below, you can see that the border engrave is off (see bottom right of the image below). Note: There is another photo below showing the stock in a metal square to demonstrate that the stock was perfectly square. Since my machine is on a QCW frame, I don’t believe the feet can be out of square. So I tried the string across the center trick to check to see if the frame was torqued. I removed the limit switches and put screws in each corner of the top rail. All were in the same place and tied tightly. The taunt strings touch perfectly where they cross no matter which one is on top (see first image below).

I also disconnected my stepper motors and loosened the four screws holding each mount for the Y axis where it connects to the X axis. I moved the rails all the way forward and retightened the bolts and connected the stepper motors again.

I posted a third image that shows how I have anchored my stock. The two long bars have overhanging lips. So the stock cannot move when it is being cut.

Neither of these fixes worked. I am baffled. I would appreciate your help getting this solved.

cheers,

jrg

This might be a stretch, but did you check to see if the file is square to the x and y axis?

In Vcarve its possible to inadvertently rotate the vectors.

To check, mirror the vectors, if they are out of square, they will magnify the error.

Good thought, but yes, I checked. It is square to the x axis. I always snap to the axes when I create boxes or squares. It cuts perfectly in the CAM simulator, so I know it has to do with my physical machine somehow.

cheers,

jrg

Did you check out this post

Ken,

I had not seen this one. I will read through the full thread and see if I can figure out possible changes that will help my issue. Thanks for bringing it to my attention. I’ll post a follow-up either way.

cheers,

jrg

Problem Solved! So I made two changes. I loosened all of the bolts holding down the rails to the QCW frame, used a clamp to insure that the rails at the front were perfectly flush with the QCW and then retightened. I also reset my hold-down system, which was not square to the waste board. I figured that the touch probe would account for any degrees off in clamping, but perhaps I was wrong about that. Between the two things, I got the problem solved. And I learned a good bit more about squaring the machine to the waste board. All good. Thanks all for your help.

cheers,

jrg