Hello everybody.

I finished installing my new spindle today and I tested it.

Everything is OK

I realize that the work starts at the same time as the spindle.

I would like the work to start only when the spindle has reached its working speed.

Is it possible?

Now I press play to start, pause for the spindle to go up to its working speed and play again to start the job.

I know that you can modify certain startup parameters on a recurrent basis.

I thought there was probably a solution here.

I may have searched badly but I didn’t see anything on it.

Can you help me?

Thanks

Hey Fred,

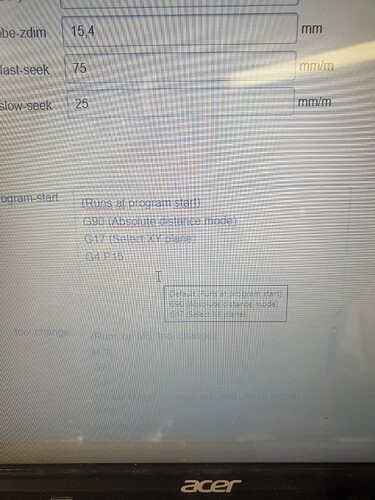

which CNC controller do you use, the buildbotics.com-derived Onefinity Controller or the Elite/Masso? If the first, yes, you can add a G4 (Dwell) command in the ‘program-start’ and then of course also at the end of the ‘tool-change’ field on the SETTINGS page.

The command goes

G4 P3

where “5” is the number of seconds you can change to your needs.

Hi Aiph5u

You are a precious support. ![]()

I use the derivative of buildbotics.

You mean the “3” rather than the 5?

Ok I will try next time.

Hey Fred,

yes… The correct value depends on the individual spindle and the target speed, just try it out! ![]()

You can add dwell or pause for user input in both vectric and f360.

I did that, but it’s not good. The program waits to start but the spindle also, do I have to add M 0 between G 17 and G 4?

Hey Fred,

you are right, the command only makes sense after the M3 command. My fault. It’s the duty of the g-code program to give the M3 command at the right moment, so it is the best, as @AndyP already mentioned, to let the CAM program to insert it. Also M3 command only works when S has been set. If S is 0, M3 does not start the spindle.

No problem.

I’m very happy to have found it alone even if it’s not much.

I feel like I understand what I’m using. ![]()