New design & set up coming this week.

One of the coolest designs I’ve seen. Are you still iterating the design?

Fantastic! I can’t wait to see what you’ve done. I’m new to both CNC and CAD. I recently put in an order for a journeyman and was going to base my table build on yours. It’s the best design I’ve seen.

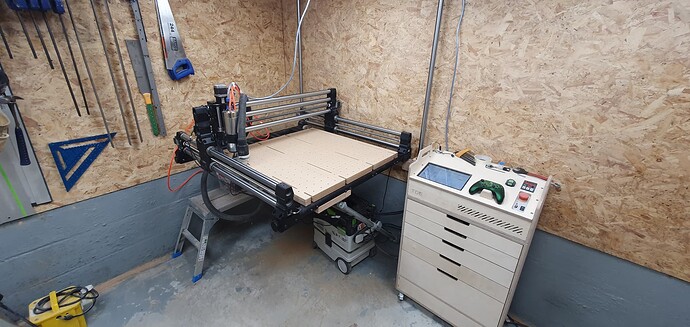

Love the cabinet build.

+1, that is really nice and clean!

Love the design and execution!

Can’t wait for the video.

This is a fantastic design, and exactly the kind of thing that would allow me to use the Journeyman in my cramped space (albeit a tiny bit bigger than what you have).

What are you using for the pivoting sliders on the rails?

Looking forward to the build video!

This is an incredible design. I love that it allows for operation on the wall or flat and that it uses the QCW for structural support.

I’ve been wanting a Onefinity for a while but have been holding off based on a combination of space constraints and and worries about the convenience of operating vertically and this would solve my issues.

Do you use the attach from above or attach from below QCW?

I would be very interested in plans or at least a list of the mechanical parts when you have it.

Awesome job and thanks again for sharing.

Ill do my best to get this done, I work full time and am moving shop soon so its all up in the air a bit!

This is a fantastic design that would work great in my shop. I would love to know where you end up and what if any special parts that you are using beyond the pipe. Is the QCW frame rigid enough to only use that as the structure? Since it ends up being cantilevered to some extent is there any flex or torsional movement in the frame when you are moving it from horizontal to vertical?

would love to build this. please let w know if you have plans for sale ![]()

@TDE can you provide any details about how you attached the hinge plate to the wall end of the QCW frame? I have a sense of how to attach the structural leg flanges through the tubing, but curious about how the linear rails are attached at the back of the OF

I have updated the design! Folding Table MK2 Update - Stronger Design - Part 1 - YouTube

Here maybe?

Kee Klamp Fittings - Threadless Pipe Fittings - Buy Kee Klamps Online | Simplified Building

Hi Lee - any chance you could share the parts you used? It seems like a really excellent design I would like to replicate! I enjoyed the video - I’d be interested to see plans too!

I’ve been looking at this product… VEVOR Linear Guide Rail 2Pcs HGR20-2000mm Linear Slide Rail with 1Pcs RM1605-2000mm Ballscrew with BF12/BK12 Kit Linear Slide Rail Guide Rail Square for DIY CNC Routers Lathes Mills | VEVOR US

It appears that with the ball screw and linear guide rails, there is quite enough load capacity. What I like about these guides vs the linear bearings is the guides can be attached to the wall at several different points instead of just two.

After building my Elite on a QCW frame, must admit I am concerned about that much weight on the wall like that. Not sure what kind of wall Lee has, my walls are 2inx6in wood framing members on a concrete foundation. The foundation is exposed at the bottom and only rises about 30cm.

I am starting to believe that any plans of this nature should have a complete finite element analysis of the system while both extending and retracting. It only makes sense to understand the forces in play and be able to personally assure that a given installation environment has multiple times the strength required at every attachment point.

What would be helpful is somehow getting this model into Fusion 360 or otherwise to start understanding the FEA profile. I saw from Lee’s video that he is using Autocad Inventor.

It seems like we have a lot of work ahead of us if we want to safely use this design.

@orangesauce I was also intrested in Lee’s design a couple years ago when he was first working on it and I ended up following the design for the most part but adapted with my QCW frame and a subframe using 8020 that uses these linear rails as they attach in multiple places and have a solid aluminum glide/slide that I felt more comfortable with. https://a.co/d/7nxi4nw

I also have a full model built in fusion360 that has working joints so it can be simulated. Happy to share if this is of any value.