My goal is to use rotary like pictured in the picture that looks like a lathe how can I do this using current 1f if that Is possible without buying new controller cool

The good news is that it has already been done and proven to work by at least one member of this forum. I believe they used it for engraving a bottle as it turned on the rotary axis. It requires the disconnection/disabling of one of the axes, the Y I believe as only Z and X axis motion is needed along with the rotary. I think they just switched the cables between the two stepper leads (maybe you will need to do some simple motor connections). The settings will also need to be changed in the controller for this new axis as the parameters are different. I am not sure if the 1F controller/software allows the rotary axis movement to be measured and controlled in degrees or only linear. I am also unsure if the 1F can save different machine setups - if yes you can easily switch between rotary and normal machine settings.

Do a search in the forum for ‘4th axis’ or ‘rotary axis’ and perhaps you will find them. Or, hopefully others who remember that member’s work will help out if they happen upon our discussion. I will take a look later as well.

Yeah Rodger has done it I have done it also

It works only with Engraving with the laser with the jtech laser but as far as carving with a bit and the Z axis moving an X axis moving could not figure out how to change the coding as far as I know no one has done that yet

It was in this post towards the bottom that talks about that setup.

This is what I got from roger

Onefinity Laser ROTARY (MM) .pp (5.0 KB)Processing: Rotary Setup for Onefinity.docx…

Processing: Rotary Setup for Onefinity.docx…

I would be surprised if you couldn’t edit the post processor for vcarve and use it with the rotary. I mean they are wrapping the Y axis in their PP for the demon controller just like I did for the laser. So I would think you would be able to do some tinkering with the PP for vcarve to get it to work with the onefinity controller.

That’s what I was hoping I’ve spent plenty of hours trying to Tinker with it when I run G-Code the rotary attachment just kind of jitters can’t seem to get it I have been looking at the demon controller thinking of attaching that I would gladly pay someone if they could figure out the post processor for the one finity I don’t have to change controllers

I’ll try and get out there tonight or tomorrow and fool around with it and see if I can come up with anything. It’s been flooding here recently so it’ll depend on the weather and if it’s lightening. But if I get something working I’ll report back to you

Amen

That’ll be great

I know I’m not the only one hoping forthis

Ty

How do you have the 1F treat degrees as linear motion? I had trouble with the first SheetCam Masso PP I tried, and when I asked about it, I was told it treated 360 degrees as a fraction of 1. I found another one that treated the rotation as out of 360 degrees and it fixed the issue. Wondering if there may a related issue you are seeing - one of dissimilar units used for linear movement.

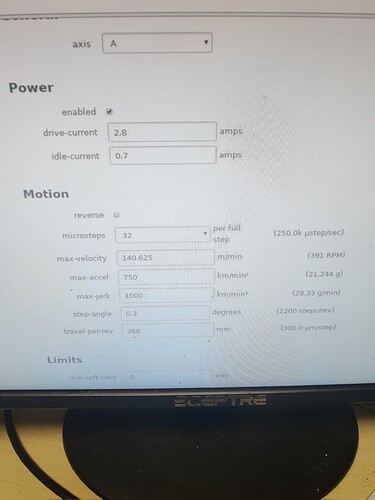

This is the change that I make to the motor and the settings on the 1f I got this from Rodger

Change the axis from Y to A. Change your “travel-per-rev” to 360. This will have to be the case for all rotaries for our controller as it is. Change the “step-angle” to whatever is mentioned for your rotary, mine was stated to be 0.3 degrees.

About midway on this page Demons PP is

here is one I was tryingGregsRotary1F (Inch).pp (5.1 KB)

I am praying, I bought the 1F CAUSE BUILDBOTICS SAID ROTARY WAS COMING BASICALLY, i AM WONDERING IF DEMON IS USING A DIFFERANT FORM OR VERSION OF GRBL

Yeah so you have to treat the travel per rev as 360mm, like when it says travel 1mm you travel 1 degree. This means you will work in Metric units. I’m sure you can do some conversions in gcode to be able to use inches but it’s easier for me to stick with MM when I’m using the rotary. Also, I’m cutting a small test piece right now in the shop here’s a short clip just showing that it is working as expected. Will show the end result when it finishes. Might want to turn your volume down before watching VID_20210920_200351.mp4 - Google Drive

The lengthwise notch in the wood is for a window pane not from the onefinity cutting lol. It’s what I had on hand.

Also, here is the post processor I edited for this: Onefinity ROTARY (MM).pp (5.0 KB)

fixed the link on drive

I believe you are going to have to use a MM PP from the way I setup the motor. Unless you can do some calculations inside the PP. I say this bc I tried Inches first and it was rotating my stock 360 inches when it should have been 360 degrees and we told the controller 360mm = 360 degrees for our rotary.

Mr Rodger hello sir man thank you now the changes to the motor 1 or theY1 settings are the same as you shared earlier where it goes from 1.8 to .3 and 10 to 360

Also are you using vcarve Pro or aspire for your designing software and you’re using the wrapping

I’ll be trying it first thing in the morning sir if it works I am willing to pay for your time I don’t know if that’s ethical or not if so if you still have my email shoot me a payment method thank you again sir

Haha no need for payment we are all here to learn. My Darth Vader helmet has about 15 mins left to carve and I’ll show you the result.

Yes sir Mister Rogers I highly appreciate your help I pray one day I’ll be in the teaching position where I could pay it forward God bless