Hi there,

I’m looking for recommendations for the feed rate, plunge rate, and the depth per pass for a 1/2" diameter by 1/2" height by 1/4" shank keyhole slot bit. I can’t seem to find specific information on this particular bit, and I’m trying to set up a project using my Onefinity woodworker. This is my first time making keyhole slots and using this bit, and I want to make sure I get the settings right to avoid breaking the bit on my first try.

Thanks!

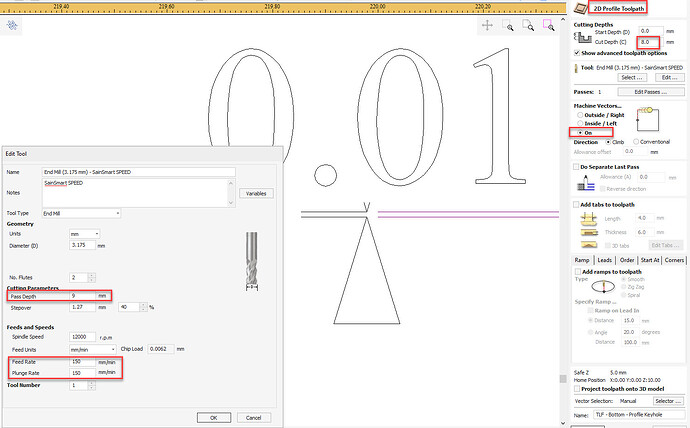

Screenshot below showing the vector and settings that work well for me when using a 1/4" keyhole bit.

I draw a rectangular vector, as long as needed, with one end open and at the specified distance. The two lines are almost exactly on top of each other, separated by just .0004 inches (.01mm), which is nearly imperceptible. This effectively makes the bit move in one direction and then double back onto itself, as you would if operating the bit manually.

I select a random 1/8" end mill because, again, the software or machine doesn’t really need to know it’s a keyhole bit.

For my bit, a depth of cut of .32" (8mm) works best. Ensure that the bit is configured with at least this much set for Pass Depth, as you want the entire operation completed in one smooth movement—no ramps either!

Both the feed rate and plunge rate are set very low at 6" (150mm) per minute, but the entire operation takes less than 30 seconds.

1 Like

Hi There, @SurfinGump

Thanks for the detailed response. I really appreciate you taking the time to share those details. Everything you mentioned sounds great.

I just wanted to confirm whether the feed and plunge rates you provided were suitable for a 1/2" diameter bit or if they were specific to your 1/4" diameter keyhole bit.

My bit has double the diameter of the one you mentioned, so I wasn’t sure if I needed to adjust the settings accordingly. I apologize if my question seems uneducated or redundant.

Thank you for being so helpful.

Best regards,

Manny

I would think so, but being cautiously conservative is not a bad thing when it comes to keyhole bits IMO. The reason I have mine set so low is because at least with the cheap-o keyhole bits I bought, they tend to burn/smoke easily.

With that said, I would hope 4" (100mm) per minute would be the slowest feed/plunge rate required, even for a 1/2" bit.

Also to note, I didn’t mention RPM, but in general I tend to set this around 14-16 K and leave it there for just about everything. I don’t have my spindle plugged into the CNC controller, primarily for the purpose of being able to control the RPM during carving, which you can obviously do if using a Makita router. Keep an eye, or should I say an “ear” on the operation, if you see or hear it struggling, chopping, chattering, skipping, burning, smoking or any other negative verb, start tweaking the RPM very slightly up or down. Granted with the short duration of a keyhole toolpath, you may not have enough time to effectively dial-in the RPM, but that’s why they invented scrap wood!

Basically, the rule of thumb I like to keep in my mind when picking speeds is, about how fast would I go if I was doing this by hand with a router? Start there and work your way up or down.

Just a reminder, carving a keyhole is such a short amount of time by nature, going slow may actually make it feel worth the time it took to create the toolpath and change the bit =]

1 Like

Hi @SurfinGump,

Thanks for the follow-up information. Your input has been very helpful, and I’m now feeling more confident about taking the plunge (see what I did there?)  .

.

I’ll pay attention to all the details you mentioned, and hopefully, my smoke detector won’t go off if there’s any burning or smoke.

Thank you for taking the time to help me out with this. I usually enjoy finding answers, learning by doing and utilizing available resources. However, I haven’t found any resources besides “complicated spreadsheets,” which I appreciate, but I struggle to interpret them to find my answers to figure out feeds and speeds and all that jazz.

I’m glad we still have the “old-school” human approach to learning, where wisdom and experience from others guide and help us learn and teach rather than relying on Google searches and the now ever so popular “introverted, lonesome approach” to self-learning.

I’m grateful for your time.

Cheers!

Manny

1 Like

Hi there! It worked like a charm!!! Thank you for being so helpful. I’ve successfully made a number of these and they worked great with your recommended settings!

1 Like