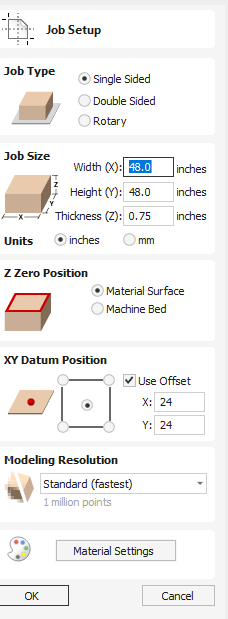

I am trying to be a fist time user of Elite Foreman, having trouble with the B Hard Limit Alert. I am running a job to setup my spoil board with screw hole and threaded inserts. I created the job in Vectric Vcarve Pro.

I have no issues jogging the machine all around the table. I have gone through the normal job setup procedures, Home Machine, set X, Y and Z, I wanted to do a dry run first so I went to MDI and selected Dry Run, Loaded File, move my machine to roughly the middle of the table, hit Rewind, hit Cycle Start(asks to load Bit), the machine jogs to the bottom left corner, then moves about 2 inches towards the first hole then triggers the B Hard Limit Alert.

G Code:

(VECTRIC POST REVISION)

(75AB5F8389AD6D58DFBB85F299EC2A67)

( Screw Holes_1-2-Screw Pocket 1_8 UC )

( File created: Saturday August 09 2025 - 10:13 AM)

( for Masso from Vectric)

( Material Size)

( X= 48.000, Y= 48.000 ,Z= 0.750)

()

(Toolpaths used in this file:)

(Screw Pocket 1/8 UC)

(Screw Holes 1/8 UC)

(Tools used in this file: )

(1 = UC2175 - Upcut - 1/8"x 3/4" )

N14 G00

N15 G20

N16 G17

N17 G90

N18 G80

N19 M08

(UC2175 - Upcut - 1/8"x 3/4" )

N21 T1 M06

N22 G00 Z0.8000

N23 S18000 M03

(Toolpath:- Screw Pocket 1/8 UC)

()

N26 G94

N27 G00 X0.0000Y0.0000

N28 G00 X2.5000 Y1.2500

N29 G00 X2.5000 Y1.2500 Z0.2000

N30 G1 X2.5000 Y1.2500 Z-0.4375 F35.0

N31 G00 X2.5000 Y1.2500 Z0.2000

N32 G00 X2.5000 Y16.4100 Z0.2000

N33 G1 X2.5000 Y16.4100 Z-0.4375 F35.0

N34 G00 X2.5000 Y16.4100 Z0.2000

N35 G00 X2.5000 Y31.5700 Z0.2000

N36 G1 X2.5000 Y31.5700 Z-0.4375 F35.0

N37 G00 X2.5000 Y31.5700 Z0.2000

N38 G00 X2.5000 Y46.7300 Z0.2000

N39 G1 X2.5000 Y46.7300 Z-0.4375 F35.0

N40 G00 X2.5000 Y46.7300 Z0.2000

N41 G00 X16.8500 Y46.7300 Z0.2000

N42 G1 X16.8500 Y46.7300 Z-0.4375 F35.0

N43 G00 X16.8500 Y46.7300 Z0.2000

N44 G00 X16.8500 Y31.5700 Z0.2000

N45 G1 X16.8500 Y31.5700 Z-0.4375 F35.0

N46 G00 X16.8500 Y31.5700 Z0.2000

N47 G00 X16.8500 Y16.4100 Z0.2000

N48 G1 X16.8500 Y16.4100 Z-0.4375 F35.0

N49 G00 X16.8500 Y16.4100 Z0.2000

N50 G00 X16.8500 Y1.2500 Z0.2000

N51 G1 X16.8500 Y1.2500 Z-0.4375 F35.0

N52 G00 X16.8500 Y1.2500 Z0.2000

N53 G00 X31.2000 Y1.2500 Z0.2000

N54 G1 X31.2000 Y1.2500 Z-0.4375 F35.0

N55 G00 X31.2000 Y1.2500 Z0.2000

N56 G00 X31.2000 Y16.4100 Z0.2000

N57 G1 X31.2000 Y16.4100 Z-0.4375 F35.0

N58 G00 X31.2000 Y16.4100 Z0.2000

N59 G00 X31.2000 Y31.5700 Z0.2000

N60 G1 X31.2000 Y31.5700 Z-0.4375 F35.0

N61 G00 X31.2000 Y31.5700 Z0.2000

N62 G00 X31.2000 Y46.7300 Z0.2000

N63 G1 X31.2000 Y46.7300 Z-0.4375 F35.0

N64 G00 X31.2000 Y46.7300 Z0.2000

N65 G00 X45.5500 Y46.7300 Z0.2000

N66 G1 X45.5500 Y46.7300 Z-0.4375 F35.0

N67 G00 X45.5500 Y46.7300 Z0.2000

N68 G00 X45.5500 Y31.5700 Z0.2000

N69 G1 X45.5500 Y31.5700 Z-0.4375 F35.0

N70 G00 X45.5500 Y31.5700 Z0.2000

N71 G00 X45.5500 Y16.4100 Z0.2000

N72 G1 X45.5500 Y16.4100 Z-0.4375 F35.0

N73 G00 X45.5500 Y16.4100 Z0.2000

N74 G00 X45.5500 Y1.2500 Z0.2000

N75 G1 X45.5500 Y1.2500 Z-0.4375 F35.0

N76 G00 X45.5500 Y1.2500 Z0.2000

N77 S18000 M03

(Screw Holes 1/8 UC)

()

N80 G00 X2.5000 Y31.5700 Z0.2000

N81 G1 X2.5000 Y31.5700 Z-0.8000 F35.0

N82 G00 X2.5000 Y31.5700 Z0.2000

N83 G00 X2.5000 Y46.7300 Z0.2000

N84 G1 X2.5000 Y46.7300 Z-0.8000 F35.0

N85 G00 X2.5000 Y46.7300 Z0.2000

N86 G00 X16.8500 Y46.7300 Z0.2000

N87 G1 X16.8500 Y46.7300 Z-0.8000 F35.0

N88 G00 X16.8500 Y46.7300 Z0.2000

N89 G00 X31.2000 Y46.7300 Z0.2000

N90 G1 X31.2000 Y46.7300 Z-0.8000 F35.0

N91 G00 X31.2000 Y46.7300 Z0.2000

N92 G00 X31.2000 Y31.5700 Z0.2000

N93 G1 X31.2000 Y31.5700 Z-0.8000 F35.0

N94 G00 X31.2000 Y31.5700 Z0.2000

N95 G00 X16.8500 Y31.5700 Z0.2000

N96 G1 X16.8500 Y31.5700 Z-0.8000 F35.0

N97 G00 X16.8500 Y31.5700 Z0.2000

N98 G00 X45.5500 Y31.5700 Z0.2000

N99 G1 X45.5500 Y31.5700 Z-0.8000 F35.0

N100 G00 X45.5500 Y31.5700 Z0.2000

N101 G00 X45.5500 Y46.7300 Z0.2000

N102 G1 X45.5500 Y46.7300 Z-0.8000 F35.0

N103 G00 X45.5500 Y46.7300 Z0.2000

N104 G00 X45.5500 Y16.4100 Z0.2000

N105 G1 X45.5500 Y16.4100 Z-0.8000 F35.0

N106 G00 X45.5500 Y16.4100 Z0.2000

N107 G00 X45.5500 Y1.2500 Z0.2000

N108 G1 X45.5500 Y1.2500 Z-0.8000 F35.0

N109 G00 X45.5500 Y1.2500 Z0.2000

N110 G00 X31.2000 Y1.2500 Z0.2000

N111 G1 X31.2000 Y1.2500 Z-0.8000 F35.0

N112 G00 X31.2000 Y1.2500 Z0.2000

N113 G00 X31.2000 Y16.4100 Z0.2000

N114 G1 X31.2000 Y16.4100 Z-0.8000 F35.0

N115 G00 X31.2000 Y16.4100 Z0.2000

N116 G00 X16.8500 Y1.2500 Z0.2000

N117 G1 X16.8500 Y1.2500 Z-0.8000 F35.0

N118 G00 X16.8500 Y1.2500 Z0.2000

N119 G00 X16.8500 Y16.4100 Z0.2000

N120 G1 X16.8500 Y16.4100 Z-0.8000 F35.0

N121 G00 X16.8500 Y16.4100 Z0.2000

N122 G00 X2.5000 Y16.4100 Z0.2000

N123 G1 X2.5000 Y16.4100 Z-0.8000 F35.0

N124 G00 X2.5000 Y16.4100 Z0.2000

N125 G00 X2.5000 Y1.2500 Z0.2000

N126 G1 X2.5000 Y1.2500 Z-0.8000 F35.0

N127 G00 X2.5000 Y1.2500 Z0.2000

N128 G00 Z0.8000

N129 G00 X0.0000 Y0.0000

N130 M09

N131 M30

%