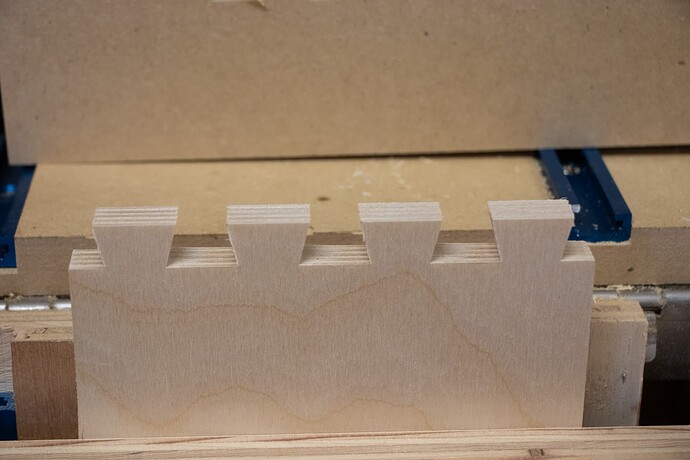

Dovetail success! Put my new drop-in vertical fixture to use, made my first dovetail box drawer today. Really happy with the quality. My setup allows me to rotate and swap boards without needing to touch the 1F’s settings - ran all of the tool paths with the .25" down-cut bit first, then re-mounted the boards for the dovetail bit. Worked great!

Had to tune the settings of my probe - it was off a little bit and was messing things up. Accurately measuring the thickness of the plywood was also needed. Used a .005" clearance on both the pins and tails - these things fit like a glove, just a light tap with a hammer to get them to set.

Clamping the backer boards eliminated tear-out, at least I could reuse them for all the cuts on this box.

Need to fine-tune the cutting paths in Fusion - the 2d clearing passes work, but I think a simpler approach would be faster - something to play with next.

Here’s some photos of what I ended up with: