I’m in the exact same situation as Dennis, and my “shop” is half of a two car garage so space is at a premium. In speaking with the folks at OF, they suggested a table size of 48"x60". In a perfect world with a 1500 sf shop, that would be no problem, but I need to be as compact as possible. Would a table of 48"x48" be feasible? I could probably squeeze that in, but nothing bigger. I could mount the control box on the side or on a shelf underneath to save space.

Paul, with space being at a premium for you. Have you considered a flip top table as some have built for their machines? I am certain there is a thread in the forum with detailed drawings for this type of set-up.

Grant–That’s my other problem, I have no useable wall space, both sides of the garage have cabinets.

Hi Paul, I know the struggle. My table is a 60"x60" enclosure (outer dimensions), in which the machine fits well and still has a couple of inches space around it.

Keep the dimensions as stated on the 1F page in mind when designing your table/enclosure. 48x48 should indeed be enough to mount the machine. Just keep in mind where you want to put your accessories such as screen, controller, bits, (coolant reservoir if you decide to go for water-cooled spindle), etc.

PS I solved my lack of space by moving to a bigger house with dedicated workshop.  Signing the contract today…!

Signing the contract today…!

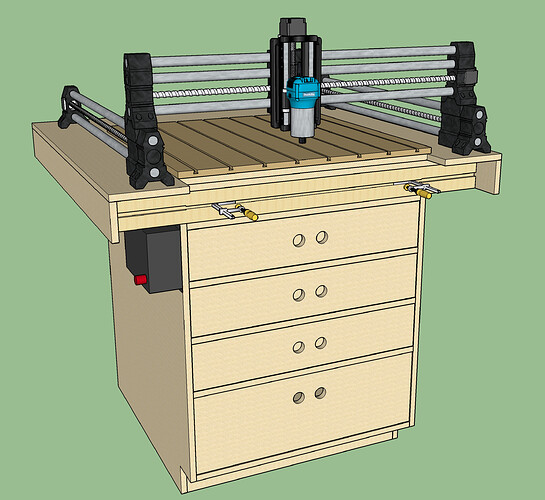

Getting ready to build my CNC Cabinet. Expecting my 1F Woodworker end of March. This is my umpteenth iteration of this design. The top is 48" x48". Cabinet has 30" x 20" deep drawers. Cabinet is 36" deep and should accommodate enough space for water coolant container in the back. Overall height is 42".

There is a cutout in the front to accommodate vertical clamping. I’m planning to use dovetail clamps on the front and the waste board design uses dovetail fixtures.

Looking for comments/concerns/suggestions before I start on this.

I like the compact design and the incorporation of vertical clamping. I do not have experience with this type of clamp, but I am thinking you would choose a hardwood for the front piece that holds the clamps? It seems like that will end up being a fixed piece, and not easily exchanged if the dovetail slots wear over time. Also, in your design, will the horizontal cabinet pieces - those which separate the drawers - be used to keep the vertical material you are cutting perpendicular to the work top? If so, perhaps recessing the drawer fronts a slight bit - 1/8" - would ensure your vertically clamped work piece will always be tight against these horizontal pieces.

If I do a 48"x48" table, I can easily add a shelf and put the accessories and control box underneath.

And…congratulations on the new house!

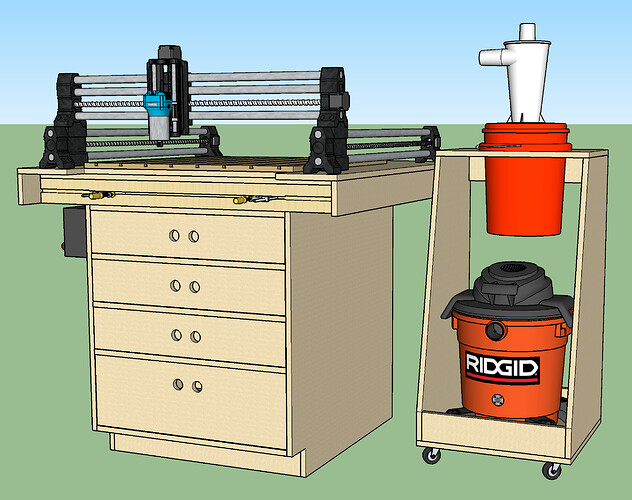

I like it. Might you also sacrifice some drawer depth and have at least a partial enclosure on the back for vacuum dust collection?

Yeah, I’m a little nervous regarding the dovetail clamps so that front board will be hard maple and will be removable in case I need to. Good idea about recessing the drawers a little so that the horizontals can provide some alignment support.

I am thinking through how to use that back space. I am planning to use a dust collection cart that I just finished but it would be good to have a dedicated setup hidden away in the back. I’d need to cut a door in the side to empty the bucket. You’re right though, I might reduce the depth of the drawers a bit.

This is my initial plan for the dust collector:

Looking good!

Definitely go with the Dust Deputy setup. I built something similar and have filled the 5 gallon bucket a couple times while building my table and other projects. Nothing but a slight haze of super fine dust in the shop vac. I used a clear/opaque bucket to be able to see how full it was.

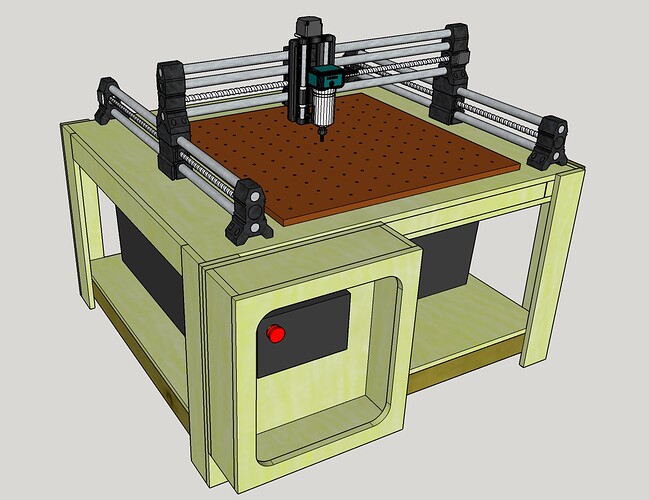

This table is about 42" deep and 44" wide. I mounted the controller in an enclosure on the front of the machine to keep dust out of the box, and to allow me to put a small light bulb to add some heat and keep the temperature warmer in the winter. I may drill a new hole and add a fan or something else for the summer months in my small, unconditioned garage. I don’t have everything set up yet, so no actual pictures to share! Hopefully I will get it all set up soon ![]()

So yeah, I think a smaller table can be done, but you can’t get much smaller (footprint-wise) than this probably.

Allen,I like your design and the small footprint would work well in my shop. Enclosing the control box is a great idea.

Looking at these tables there seems to be two schools of thought. Very stout and heavy or somewhat less robust but more convenient (example) foldable, thinner materials for legs and top. Just wondering if anybody using the less robust designs has noticed any issues with vibration, shake, or movement that is being transmitted into the workpiece.

I have a very similar set-up as what is drawn, both table and cart with dust collector and am very pleased with it. I would be concerned about putting/hiding in back. Being able to see and quickly dump the bucket when I need to is nice. Hidden in the back will make more of challenge…especially if against a wall.

I’m using Keegan ACS Legs for my folding table. I don’t fold it up and move it around often, but when I need to, it works great. I do notice that when my cuts are doing rapid moves it does experience a little sway, but just a little. Once I got the spoilboard flattened and Z trammed, it has been very stable surface for holding work pieces. For me and the work that I’m doing this is acceptable. I knew this would be a trade off for the portability factor. Others work may require a completely rigid setup. It just depends on what you are comfortable with.

Would anyone be willing to share their 1F 3d model? Not great at modelling in Sketchup.

The model I have came from the 3D Warehouse. Looks like it is no longer available from the warehouse.

I can share my copy but I can’t upload a Sketchup file to this forum as it won’t recognize the file type.

tim

I would be interested in a copy.

Andrew Brown shared a model of the 1F Woodworker at one point but it is in a fusion 360 format. You can probably search and find it. I’d share but I’m on my phone at the moment.