I just got my Elite Foreman setup and running but I am running into an issue that is driving me nuts. I’m sure it is something simple but I can’t figure it out to save my life. I am just trying to do a simple test file. Its just a 4" circle that I’m trying to mill down to about 1/2" using a .25 bit. It seems to look and simulate correctly in Carveco, so I save my toolpaths and transfer the file to the machine. I home the machine and then use the touch probe. When I start the program, the z position begins way high and the x and y positions are way left and forward. Any input will be greatly appreciated.

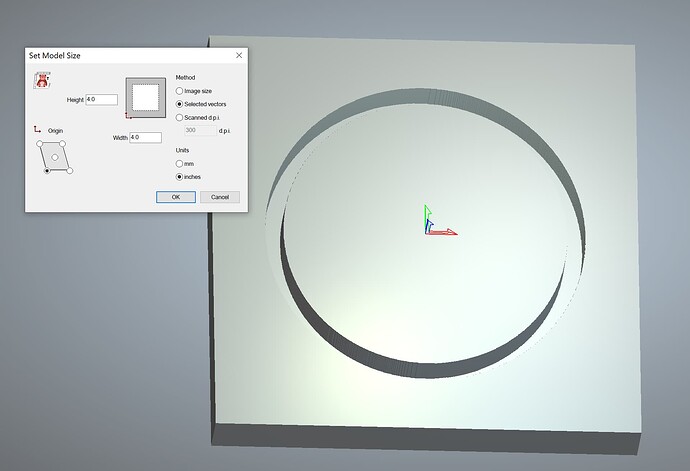

So by what you describe it sounds like the origin in Carveco is set to center of the circle and the bottom of the part. And it sounds like on the machine you set the origin to the front left corner and top of the part.

That would make the z position way high and the x and y positions way left and forward.

Well somebody that knows Carveco is going to have to say whether that screen looks right.

It does not not to me since the three arrows are in the center of the circle.

Usually those three arrows indicate where the origin is.

But again somebody who knows Carveco is going to have to say for sure.

Hey Keith,

you got to set your real workpiece’s workpiece zero exactly where it is located in your virtual 3D model. This is the way you ensure that your CNC machine knows where the workpiece is. So if you have the zero coordinate (“model origin”) at the center in your virtual 3D model, you got to make sure you probe or manualy set the workpiece zero also exactly at the center of the real workpiece. But If you have the zero coordinate on the top front left corner of your 3D model, you got to probe or manually set the workpiece zero on the top front left corner of the real workpiece too.

The machine will assume that this way you show it where it is, as otherwise the machine wouldn’t know where it is in relation to the real workpiece.

Yay that looks good! It’s all a fun learning experience.

Welcome on board.