I have little to no experience with milling metals. I was hoping someone with experience would be able to tell me their opinion on if they feel the apprentice would be a good option. I have an Elite foreman now and this would be a small, dedicated machine for metals. The bonus I see are the ball screw covers since metal shavings go everywhere and my thoughts are since its so small the deflection with the 35mm rails would be minimal?

In the video they presented, they said it’s for light work meaning small wood signs etc.

I would think it would be an ideal machine for soft metal, the guid tubes being shorter should equate to more rigidity, not sure if it supports a spindle but that would be my choice if it is available.

Pat

I agree, and it should work well paired with a 65mm (Er11?) spindle.

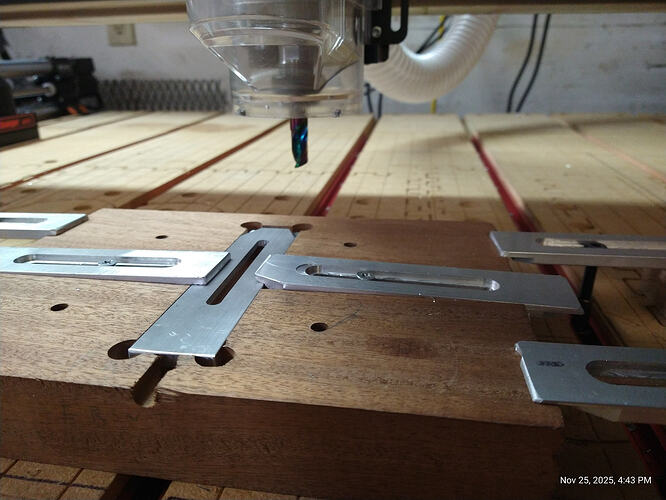

I am waiting for the first videos of it showing what it can do. ![]()

The size appears to be excellent from a rigidity perspective. Sheet material is often 48” wide, so you would be giving up the convenience of loading full width sheets.

I suspect you will want to confirm the controller supports M07 (Mist Coolant On) and M09 (Coolant Off). You’ll definitely want these to be automated, as the repercussions to forgetting these actions can be very annoying and expensive.

It should be fine.q I am doing aluminum on my elite journeyman with the stiffy. and it is working great. you have much more problems finding the right feeds and speeds than with deflection due to tubes.

I checked the Redline website and M8 and M9 are there and are configured to trigger an output. There is no M7 ‘currently’, but we can request it. M8 should work for now.

M7 support has been added in the next software release (1.1.2)

That is amazing! Thank you for being so responsive to user input - it’s appreciated.