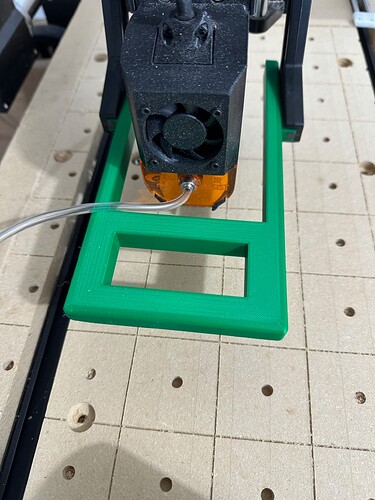

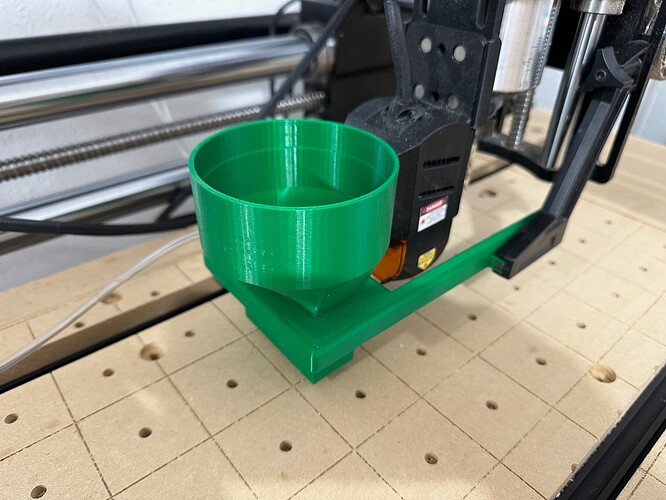

I ended up designing and 3D printing a bracket and a 4" hose adaptor.

Oooo, that’s nice.![]() Adding a few extra characters here to make up for my brevity.

Adding a few extra characters here to make up for my brevity.

nice, would you mind sharing the design file? Id love to tinker around and tweak that for my setup. I like that it uses the suckit arms as well.

Hi @makermatt ,

Here is the design file (Fusion 360).

Please share back if you have interesting tweaks.

LaserFumeAdaptor v15.f3d (236.3 KB)

I would look into making a wet scrubber for the fumes. They are pretty simple and should work well.

could you expand on this idea? I just googled them and am curious how you would hook this up for a laser. Love the idea of sequestering the particulates, but don’t understand how this would remove the fumes.

thanks in advance

A wet scrubber basically replaces a filter which will plug up. The concept is to use a water pump to spray water in the top of a tube. Below the spray nozzles are a number of plastic balls that are open like a skeleton. Your dust collector’s exhaust is ducted into the side of the tube near the bottom and the fumes are pushed up through the balls and out the top. The water rinsing down cleans the fumes. At the bottom of the tube is a reservoir with a pump attached to it to catch the water. When the water gets dirty you just replace it.

I just started using the Jtech Pro Laser and got it all set up. However, after running it for around 20 minutes on plywood, my garage ended up filled with smoke.

I’m wondering if there are specific types of wood or alternative materials that don’t create as many fumes. Also, if anyone could share their ventilation or fume exhaust setups, that would be really helpful for us!

I have a dedicated laser and would never run it without exhaust and air assist to extinguish flame ups. I want a laser for my Onefinity but I currently don’t have a good way to exhaust so I haven’t bought one. I would imagine you need an enclosure with a 4” exhaust fan and ducting to suck the exhaust outside. If you laser acrylic this is an absolute must because of the fumes. Some would say in that instance you need a scrubber.

I totally agree. I have a stand alone laser and I would never consider an open bed diode laser.

The diode lasers are toys compared to even a mediocre co2 laser. You are asking for problems

using the diode laser especially if you cut any type of acrylic.

Which budget options do you recommend?

Looks like a great solution. Going to print it out and try!

We use this in our warehouse: https://amzn.to/4ezY8aM

I use a dust boot and just remove the front nose of the boot and turn on the vacuum and suck the smoke off with the shop vac. on the exit of the shop vac I use aquarium active carbon foam filters to get rid of the smell. use the same thing on all of my ABS 3d printers and it eliminates 100% of the smell.

If you use this method just be mindful of the potential for embers and sawdust dancing together… It can be quite a sight if not attending to it… You could probably do the same with a damper/duct fan and avoid the combustibles.

Something like this, for instance…

Spider Farmer 4-Inch Inline Duct Fan, 205 CFM with Speed Controller, Quiet EC Motor Ventilation Exhaust Fan for Heating Cooling Booster, Grow Tents, Hydroponics

In a previous post I mentioned the problems I was having with the exhaust system in my enclosure. They wound up being insurmountable so I switched out the 10" diameter fan for a two speed bathroom fan hooked up to 4" diameter hose exiting outside through a hinged vent. Works wonderfully. I would be very leery of drawing off fumes with my vacuum especially since I hooked up an air assist to the laser. Embers and sawdust is not a good combination.![]()

I value my lungs, so i bought a proper fume extractor with proper filters. It is made by Donaldson, same folks that make air filters for semi trucks etc. It was expensive but well worth the money.

While I don’t have a laser yet for my 1F I do do other types of wood burning and have a fume extractor similar to the one 1F use in their shop. Mine takes a standard 4" dust collector hose so I’ll just add a Y and two blast gates.

I built a filter stack with 4 graduated quality furnace filets and a large hepa filter designed for a laser cabinet from amazon. Wasn’t cheap but works well. Dumped a gallon of activated carbon on the second prefilter. Use a furnace blower to move air through it. If I make an enclosure and circulate the air it will work really well. At this point it works well if I manage the inlet hose so it is close to the cut. Also ha e a down draft inlet inge center of my wasteboard which helped a ton for cutting.

Kyle-I’m about to purchase a 45W laser and am trying to figure out how to handle smoke. I really don’t want to exhaust my heated air in my shop. Are you still using the Spider Farmer fan and filter? How did they work? About how many hours of use did you get with the filter? Are you able to wash/recharge the activated carbon?