Would like to countersink large (5/8”) flat head bolts in 6061 using the CNC. Since they are freedom units, the taper is 82deg. I was hoping to find an 82deg V-bit, but no dice. Anyone have an elegant solution? A ball nose bit seems really inefficient.

In Vcarve Pro, you could create a circular moulding profile of that slope, but I don’t know how efficient it would be.

Thanks for the input Ken. Would you use a ball nose mill in that case? I haven’t played with 3-D profiles much.

Thank you for sharing your approach. I’ll definitely try that once I have a corner radius bit. I’m doing it exactly wrong, but getting an acceptable result. Profile cut looks like crap because the set screw on my Lube Cube vibrated loose. As poor as this looks, it is a heck of a lot better than me trying to countersink it with a bit.

I’ve done a lot of Aluminium milling and countersinking with a 90v bit for M3 screws worked fine for me.

Thanks for replying, Andy. 90 deg makes sense for a metric fastener. The challenge is with imperial fasteners, they have an 82deg taper. I wish there were an 82deg chamfer bit.

There are 82° counter sinks available. Plunge with a slow speed and no dwell.

![]() I didn’t think to try it as it requires a 1-1/4 diameter countersink. I have a good single flute countersink but was guessing the torque would be too much for my machine/spindle at lower RPM’s. Have you run anything that size?

I didn’t think to try it as it requires a 1-1/4 diameter countersink. I have a good single flute countersink but was guessing the torque would be too much for my machine/spindle at lower RPM’s. Have you run anything that size?

Ignoring the latter snark, the ad does show you that 82* bits are readily available. A brief search on Amazon (I believe when I did it I went from search to “order now” in about 3 minutes) would reveal exactly what you need. I have a 5/8" one from Amazon. I use mine in wood although they are designed for metal countersinking.

@umbert, I believe a smaller 82 deg chamfer bit could work. It could plausibly be spiraled down. Though, with the proposed Titan bit having so many straight flutes, I’d have a hard time managing an appropriate chip load to avoid clogging it up. (aluminum).

But along this line of thinking, perhaps I could run a chamfer operation using something like this:

@WC_CUSTOMS what do you think about this approach vs a radiused endmill?

I appreciate all input. Thank you. Forums are great because of all of the perspectives.

WRT Amazon:

I’m seeing a bunch of 5 flute chamfer bits in 82deg.

Based on chip load, If I used a 1/4" 5 flute bit, I’d have to stay around 1,600 RPM to keep if from turning into a ball of aluminum. For an 1-1/4" 5 flute chamfer bit, I’d be limited to 800 RPM.

Redline recommends a minimum of 8,000 RPM

At 8,000 RPMs I can probably get by with a 1/4" single flute, which are not super common.

So the quandary is whether it is better to go this approach or use a radiused endmill as @WC_CUSTOMS proposed. It sounds like his approach sound and tested, but I can’t help but wonder if an equal or better finish could be achieved with larger increments using a chamfer bit of the appropriate angle as opposed to finishing the taper with a radiused bit.

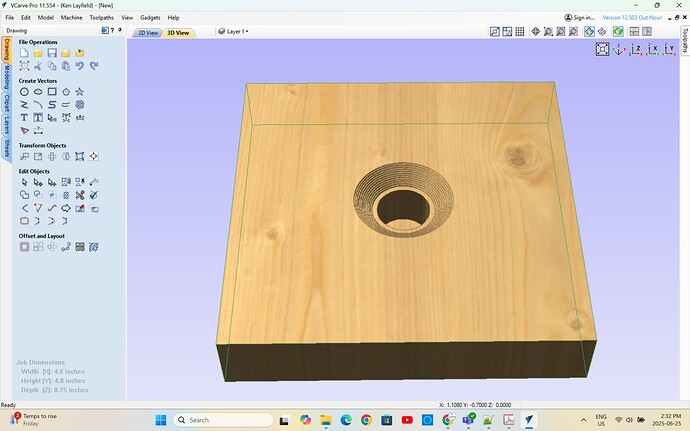

This is a 82 degree moulding toolpath for a 5/8" dia flat head.

1/4" endmill for 5/8 dia pocket and slope roughing pass

1/8" endmill for slope final pass 10% stepover

Machine estimated time 3 1/2 minutes

Thanks Ken! That looks like a great approach. I’ve been using the chamfer toolpath which only allows V-bits, Ball mills, and engraving bits. I’ll dig into the molding toolpath. Appreciate you taking the time to build and share this.

Can you use metric fasteners if you’re able? It might be more efficient than looking for an 82 countersink solution.

I would do it by hand. I use Weldon countersinks all the time. The don’t have flutes. Instead they have a hole through them and make an excellent countersink in aluminum. It takes seconds to do with a cordless drill. I could countersink a dozen holes in less time than it would take me to switch bits and have my 1F do one hole.