Biggest change I see is with the motor swap you go from 1.2 to 2Nm. Ill be honest in saying not sure how much of an improvement it is. I have wondered if I could run better swapping my motors for Massos 2 or 3Nm versions but then I would have to also change power supplies and it gets to be an ordeal.

Do you have a reference for it being purpose-built? I’ve seen nothing that indicates that from OF or Redline. And if they are related companies (more than business partnership) I haven’t found any indication of it.

If you go to the Masso site they sale it as a Masso product

go to the redline site all the items are specific for onefinity machines

If this were yesterday and the “Buy” button were activated, I would have been all over this. However, the delay gave me some time to think about whether this is really an “upgrade” or a “downgrade” from Buildbotics, which I have now. I love the visual interface of Redline but I have to wonder if there are some real shortcomings elsewhere.

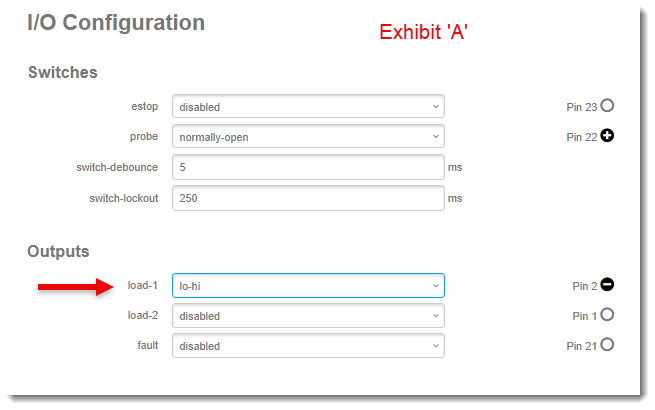

For instance, from what I have been able to glean from the marketing material, there are several things that I am led to believe that Buildbotics excels in that Redline may be a bit short in. Specifically, Buildbotics offers a tremendous amount of flexibility in I/O configuration. For example, if you look at Exhibit ‘A’ and Exhibit ‘B’, Buildbotics allows you to configure outputs to be active logic High or active Logic Low. This greatly increases the level of compatibility when trying to interface to various attached devices. From what I gather from Redline, their outputs just sink to ground and that’s all you get. There is no active logic high, so you have to get a wall wart power source to provide that capability. As if I need something else to plug in, in addition to the CNC controller, VFD spindle controller, laser, air pump, water pump and vacuum…whew, did I forget anything?

Exhibit ‘C’ allows you to configure the output to a cooling system or shop vac that will be controlled when the spindle starts/stops. In my configuration, this is set to logic high when the spindle is on and it is wired to a solid state relay that responds to logic high to turn on the shop vac. The point is, not every manufacturer designs things the same way and removing flexibility really causes you to have to engineer all kinds of kludgy workarounds.

In addition, in reviewing the 25 pin connector on Redline’s motion controller, it would be advantageous to provide a dedicated +5 or +3.3 volt output to one of the unused pins that could be used in conjunction with the outputs.

I’m thinking I may wait awhile before jumping on this “upgrade” until it matures a bit or more information becomes available.

I’m going to agree with ID here as well. The way I think about these systems is you have four major components.

- The Cutting system, either router or spindle.

- The Gantry, responsible for moving the cutting system in the X, Y, and Z planes.

- The Motion Controller, responsible for applying the power and signals to the stepping motors that control the Gantry.

- The UI/UX Software/Hardware (user interface/user experience) user facing software and hardware which allows the user to communicate the desired end result to the motion controller.

In the case of a Redline Elite system we have three players. RedlineCNC is providing the Cutting system (spindle) and the UI/UX hardware, though NOT the UI/UX Software. OneFinity provides the Gantry system and finally RealtimeCNC who are providing the Motion Controller and the UI/UX Software.

From what I see, RealtimeCNC has positioned themselves as system agnostic motion controller and UI/UX software provider, though you can’t currently buy directly from them. RedlineCNC also is a system agnostic company but you can’t currently directly buy their UI/UX hardware, though you can buy their spindles directly.

I’m going to go out on a limb and guess the OneFinity is absorbing the majority of Redlines UI/UX hardware (the touch screen/microcontroller combo) and RealtimeCNC’s motion controller capacity. This indicates pretty tight bonds between the three companies with each focused on their own core competencies. So the point that enhancement requests channeled through Onefinity may be more responsive than looking for an enhancement from MASSO, which is engaged with a much broader audience makes sense to me. These also seem like younger companies while strong out of the gate, pointing out that we really don’t know how these relationships will mature is on point as well.

Hi Tom,

We produce the motion controller hardware (and software) used in the Redline system. I can answer some of your questions/concerns.

In terms of the I/O configuration (your Exhibit A), Buildbotics does allow you to set the polarity of the output. At the moment, our outputs are just “active” which means the output switch (a solid state relay) is closed when active. It would be an easy addition for us to add selectable polarity. I have added it to our feature request list.

One important difference between the Buildbotics controller and the RTCNC controller is the number of outputs. The RTCNC controller has four outputs versus two outputs on the BB.

Another important difference is the BB outputs are fixed at the supply voltage (36V). This often means level translation or current limiting is required to interface to lower-voltage control hardware.

The RTCNC outputs are dry-contact outputs which, as you pointed out, acts like a switch that can be closed. The RTCNC outputs are also optically isolated from the controller. The BB outputs are not. We feel this makes the system more robust when faced with loads that could cause EMI issues or ground loops.

We went with a dry-contact arrangement so the end-user can easily interface it to any control voltage in their system. You are correct about there being no I/O voltage supply in the controller. This was intentional because including an I/O supply forces the user to a particular voltage standard (see BB above) and adds to the base cost of the controller. The outputs are compatible with voltages up to 50V, so it can be used in 3.3V, 5V, 12V, 24V, 36V or 48V systems (with an external supply).

A complete description of the outputs with interfacing tips is available in the manual here: Inputs & Outputs - RealTime CNC Documenation Hub

This is not entirely accurate as the outputs can be wired to sink to ground or source from an external supply. If you are interested in a schematic for the latter, check out this article from the manual: Connecting an IoT Relay - RealTime CNC Documenation Hub

Let me know if I missed anything. I’m happy to answer any questions or suggestions.

Any chance you can answer the question I sent to you (PM) at the beginning of the week?

Can the Redline controller power/function a tower light?

Secondly, I have an aftermarket tool setter that runs on an optical sensor. It requires 12-36VDC, ground and then it has either a NO or NC output. Is there a way to wire this to the controller?

Will there also be an upgrade path to bring our revolution up to elite standards (closed loop motor) as well? I would hate to get the redline and turn my revolution into a very expensive and fancy paperweight.

As I am contemplating what (if anything) to buy this year, I started toying with the idea of just purchasing the Gen 2 journeyman and selling my original series ( get the new controller, motors that I would get in the RL upgrade PLUS all of the features of the new elite). To see what would be fair to ask for my old journeyman I went over to the sales site to look at the current pricing for a Pro machine.

To my surprise, the BB versions are not even listed anymore. Is this a glitch, or are you going to stop selling the BB machines all together? If so, will you continue to support the BB machines?

Yes, there will. Half of it is already available on our site, you just need the 1.2nm (do not get a 2nm motor, it will be too long and not fit between the rails when on the machine, 2nm doesn’t add anything on the rotary) closed loop motor. The second is just the cable from the motor to the controller, which we will make available.

The Original and Pro Series (with the BB Buildbotics controller) have officially reached end-of-life. They served the community incredibly well for over five years, but with how far our machines and controllers have advanced, it only makes sense to focus on the Elite and Apprentice Series moving forward. Thanks to the Redline controller, we’re able to offer the far-more-capable Elite Gen 2 machines at the same—or even lower—price than the Original lineup.

And don’t worry for a second: we provide lifetime support for every Onefinity ever made. If you own an Original or Pro machine, you’re still a valued part of the family—we’ve got your back, always.

Yes, but so does Jtech & OPT for their lasers and they weren’t developed specifically for the OF, only that they have the appropriate adapters to make it work.

Granted there does seem to be some additional relationship between OF/Redline/Realtime that doesn’t existing with OF/Masso in that OF is the launch customer for both Realtime and Redline, though I think JTech had/has a similar relationship. They are still positioning their hardware as machine agnostic (and based on some of the replies below a buildbotics competitor) rather than an OF only option.

This is a good description. One thing I noted is the motors are branded OF, not RL/RT which adds a potential for another level of integration hell (IYKYK) unless this are white labelled parts from RT (which if it is makes me wonder why the whole RL/RT situation isn’t white labeled.

For me this is a bit of a downgrade from the level of integration that OF used with the Masso (motors, motion, and UI from Masso) to using their motors, with a separate motor controllers/software, and separate software

This is the reason for the change ![]() and a valid and a good one at that.

and a valid and a good one at that.

Question - are the 2 nm motors the same as the 2nm Masso motors? They look the same just with OF labels ![]()

![]()

Yes, The motors are the same. They aren’t technically ‘Masso’ motors, they’re independently made at a motor factory and all companies just ‘brand’ them with their branding.

Thank you for the near “Realtime” reply. :)![]()

You’ve answered my questions.

I have the BB PRO. I went with the PwnCNC 80mm air-cooled spindle last year with all the Redline delays. Any conflicts with the PwnCNC VFD/Spindle if I were to upgrade to the Redline controller? Cabling/connection changes or issues?

It might work, but we haven’t tested it nor do we offer technical support for aftermarket spindles.

The only tested, warrantied, and guarenteed to work spindle is by the maker of the controller, @Redlinecnc :

@tosbo6 The PwnCNC VFD seems to be a EM60 series VFD under the hood. At first glance, it seems to be the same RS-485 communication protocol as the Redline VFD. If there are any minor differences, we can address it with a software update.

You would need an adapter cable to plug into the RS-485 port on the RTCNC controller but we can help you out with pinouts if you decide to go that way.