I am making a handle for a mallet and carving on both sides of it. Side one, no trouble at all, but when I flip it to the second side and try to carve it In the previews in three D it shows the handle carved all the way through no matter how shallow I set the depth. I only want the carving to go in about .075 on either side of a piece that is .750 thick so there should be plenty of thickness to do it, but it seems to be showing me it is carving much deeper, as in all the way through. What am I doing wrong? I have checked the depth time after time to no avail. Is there something weird about doing two sided carves?

What program are you using?

You should be able to just use the first file twice.

vcarve pro but what do you mean use it twice? I have never tried to do a double sided carve .

Are you engraving the same thing on both sides?

yes i am . I am wondering since i am comming from the now bottom of the piece if i should put the starting depth at .750 ? I will test this theory and get right back to you

and thanks youare the only one one the forum to reply and try to help.

ok that idea did not work out it is still cutting way too deep

I do not use Vcarve but found a video from Vetric on the setup, looks like you need to use the same Z location for both sides based on your job setup of either material surface or machine bed.

I will check that out as soon as i can and thank you for your help.

ok so i viewed the tutorial it talks about setting the zero to different surfaces and somewhat explains each but this did not work for me i tried each configuration wen i set it to each one I get the perfect depth for one side then i flip the handle to the other side with the same depth settings and i carves all the way through to the other side i have I believe tride this on all three settings it does it correctly for the first side then it on the second side it carves again but all the way through to the other side of the material I need to know what in the ^&** the reason for this is.

What are you using for a zero location? I always use the top of the work piece in the lower left corner. Are you using the touch probe? If so do a sanity check. Once it’s zeroed manually move the bit to the zero position. The bottom of the bit should be just barely touching the wood. If not then there’s an issue with zeroing. Recheck to make sure you are using the surface of the project as the zero in Vcarve (I use fusion so I can’t help there).

I am afraid you do not understand. i am only in the software, not actually carving. I am doing a double sided carve the first side previews as directed at .070 deep from the surface of the material. the flip side carves right through to the opposite side every time I preview it. I have tried every way the software can be set it seems I know I am missing a point here but I’m damned if I know what I am missing.

I see. Sorry I don’t have Vcarce so I can’t help.

thank you for the attempt:) I appreciate it

yes yes i am I have tried every which way i can think of.It is always the seond side that cut all the way through the material. no matter what side i start on. i tellit to go .070 deep and it does on the first side then on the second side it plows through all the way to the first side , I have tried the different settings of surface of the material and material bed both with and witout using the same surface button nothing seems to help

I know i am missing some small basic piece of information.

If you would like for some of us to take a look at your file to see if we can spot something you might want to post the file. Don’t know that we can solve it, but it’s worth a try.

ok carrol how do i post the file/ i have never done that before

HAMMER CARVINGS ON HANDLE.crv (11.4 MB)

ok I think this is it and thank you again

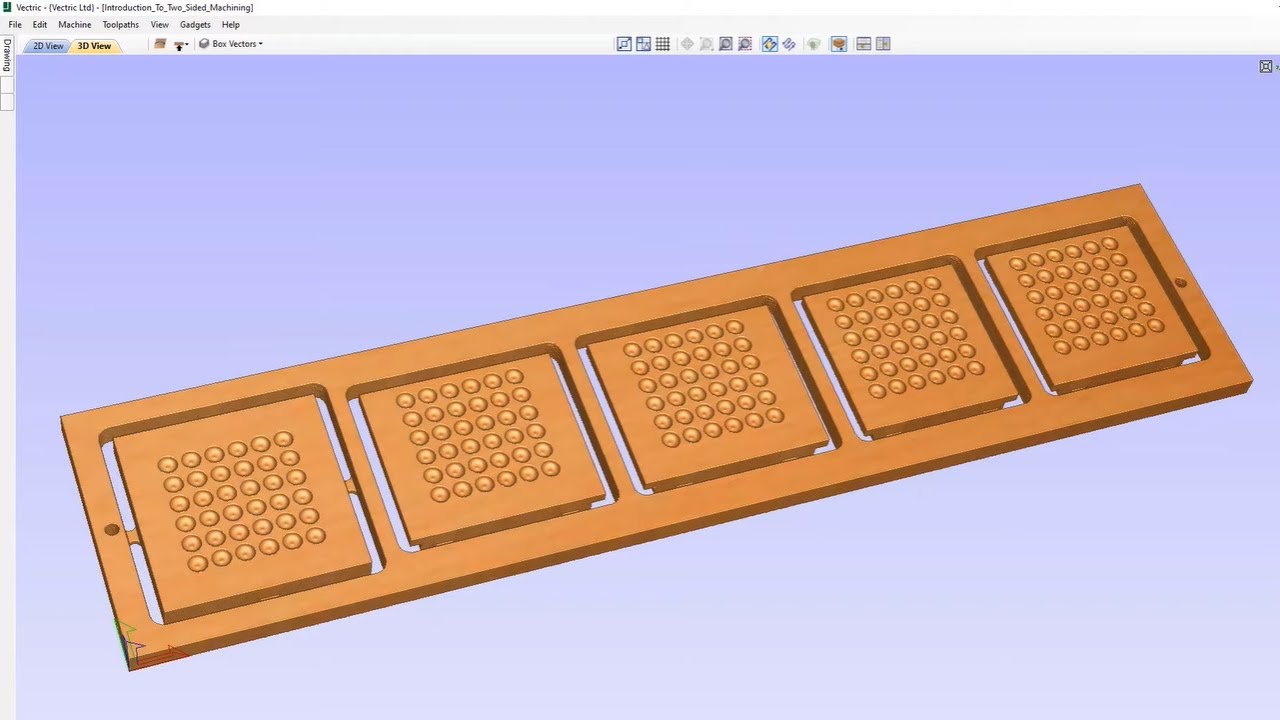

Interesting design. I took a look at your drawing and other than the outer cut of the handle being set WAY too deep, there is nothing much wrong with your drawing. But I don’t understand how you’re showing the carve on both sides in 3D when you had no toolpaths on the bottom side.

I’m sending your file back with some modifications so you can look at it. In particular, look at the layers, grouping of your ovals and X’s and how I named everything for more clarification. I also added tabs to your outer cut.

I did not clear up the overlap of the X’s where you had it.

Pony

test1 - HAMMER CARVINGS ON HANDLE.crv (17.6 MB)

as a quick answer to your comments I did not put the tool paths on the model i sent you . nor have i put tabs on yet i am still just trying to get the damned secoond side to stop plowing through the entire handle

the rest is easy

ok you seem to have solved the problem of it cutting through but HOW? what did i do wrong that kept making it cut through?