Groovy, man, far out!

Somebody knows the '60’s!

Pony

What city & state is it located in?

Pony

Cardington, OH

They are open for the season. If others are nearby, feel free to stop out!

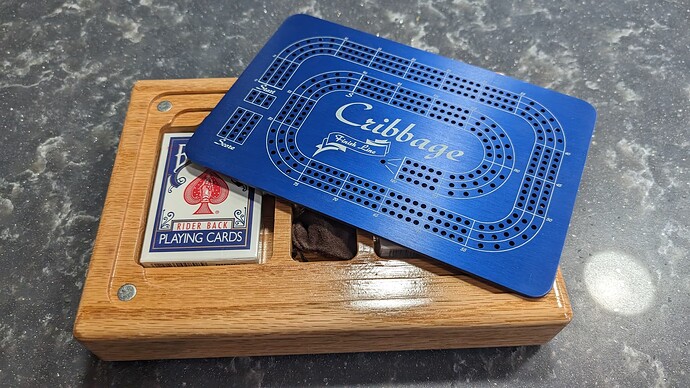

Cribbage Boards - Love how quick and accurately my OneFinity Woodworker cranks these out!

My Aluminum decks must be milled to very tight tolerances when marrying them to my wooden bases. All I can say is they “Fit like a Glove” when I get them off my 1F, the pockets are accurate and tight as well.

My customers love my Crib Boards and I’m just thankful I do not need to keep a ton of inventory anymore… just drop in the jig, run the saved carve file… sand… finish… ship. It’s awesome.

-Alex

Going to double the carve time so that I can eliminate a bit change and thus some of the artifacts that happen in the transitions. Also changing the ‘BE PREPARED’ from 60 degree v bit to 30 degree with no flat depth

Can you tell me were you got the file? I would like to do one for my son…

I believe this was the dxf I sourced Eagle Scout dxf File Free Download - 3axis.co

Thanks! I’ve never sold files before. I don’t even know if anyone other than me could figure them out. Designed in Fusion 360.

Aaron, are you from the Cardington area? I’m not far from there, just South of you.

I grew up just West of that area, moved to the South West side of Columbus, out in the country.

This project was for my 3rd Grade Teacher’s family. So it was nice being able to get back out there.

Nothing super complex, but the first real production job I’ve done with the CnC.

We make these for the tourist trade on the big island, they’re stands for painted glass hemispheres.

Knocked out about 30 of these in a little over hour (machine time). After that, about 5-10 minutes of sanding each, combo of spindle sander and hand sanding, depending on the wood species and some wood burning for the logo. We have considered going laser for the logos, but the wood burning gives them a more handmade look.

The CnC gives me a much more accurate profile and cut my sanding time roughly in half vs using the bandsaw.

Mike is there a file for this?

Here ya go. hat stretch.dxf (43.8 KB)

Just something simple I whipped up after seeing them on line. I used 3/4" cedar for mine. I believe the mass produced one are 1" or 1 1/2" boards.

I drilled a 5/16" hole in both pieces and then a 1/4"-20 bolt with the head cut off and a wing nut for adjustment.

I wanted to make my lid more into a long oval shape to better fit my melon head ![]()

Steamed it a little bit and it seems to have helped.

Thanks so much. I may try to put a threaded insert in there, as well, but figured you were using a treaded rod and the wing nut to expand it… So based on your pick and description this makes perfect sense.

Post a pic when you make one. ![]()