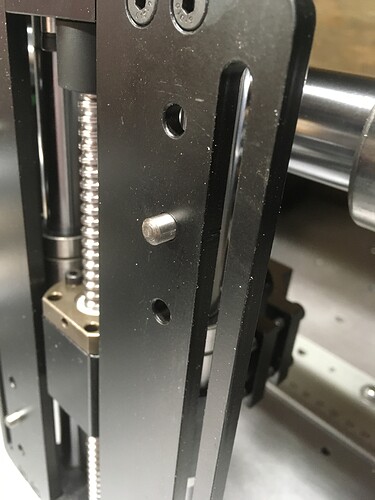

@Laserlarry, I did end up getting it completed this afternoon. I placed 6mm dowel pins in the middle hole positions of the Z axis that keep the assembly aligned by engaging the 6mm slots in the alum. extrusions. Not necessary, but very nice for keeping the Z axis aligned vertically. I used M5 flanged-head screws to attach the 20 x 20 extrusion pieces to the X axis bearing block, and then used screws in 8 locations (upper & lower hole positions) to attach the Z axis to the extrusions.

It would ultimately be better to mount the z axis in the center position, but that would require another smaller baseplate & frame assembly on top of my existing base. I may still opt to do this later, I don’t know. Note that this modification will complicate dust shoe mounting, but I don’t use one so it’s no big deal to me.