Hey Satoer,

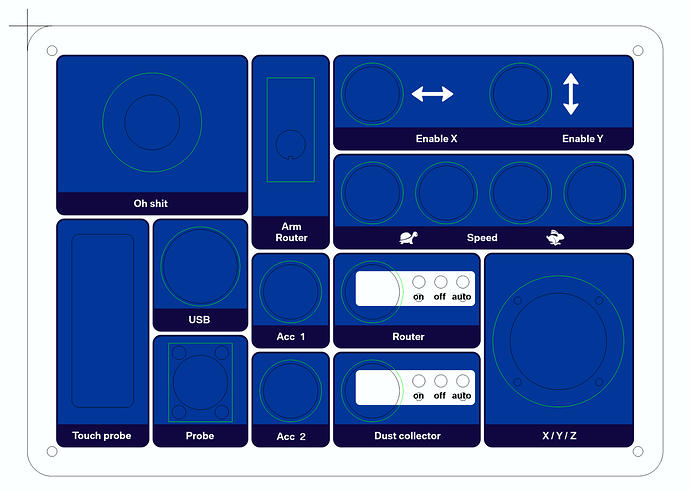

after thinking about what you wrote, I think maybe it would be best if you first bring out a Version 1.0, with just a router switch.

The possibilities of integrating spindle-related controls or information are so diverse that it will cost you time until it is clear what should be implemented and what is required or desired. Very different things could be conceivable. This is because there are at least three levels of access and / or information to the VFD / spindle.

First of all, everyone should be aware that the common use of a CNC machine is to run a gcode program. If you use a VFD and a spindle for this, then it is controlled by the program. This means that switching the spindle on and off and setting the spindle speed is controlled inside the program that is running (Gcode commands M03 / M05 and S). In this operating mode, there is no need for any control element on the control panel for the spindle.

But of course many users would like to experiment with the possibilities of a spindle “live”, like with a remote control, especially if they are still new and want to try things out. It is useful here that a VFD also allows extensive control by means of externally connected controls and buttons. But such a panel would have more controls than just one single switch. That would be the second level for something spindle-related that could be realized in a control panel.

And thirdly, with every VFD there are almost innumerable setting options that are not set by the program, i.e. not by standard Gcode. For adjusting these settings by hand, a VFD has a small control panel and a small display. This control panel is also available as an external accessory for the VFD so that you can pick it up and sit down and not have to stand at the control cabinet all the time when you set the VFD.

One such accessory for my VFD, the Omron MX2 (almost identical to Hitachi WJ200) is the Omron 3G3AX-OP05 “5 line LCD digital operator with copy function” control panel or the Omron 3G3AX-OP01 “LED remote operator panel” control panel. You could make an indentation in your control panel to put these accessores in there.

Much better, however, I would think (and I have already thought of doing that in near future) would be the question of whether one should recreate this, namely to get rid of these flimsy membrane keys and replace them with good mechanical switches from Cherry, Marquardt or Kailh (said to be the best) and replace the display by one in your favorite size and color.

However, level three is specific to the VFD model. I cannot say anything about the Huanyang VFDs since neither I own one nor have I ever seen a User’s Manual or datasheet from them.

Level two should offer at least some similar control or information options for most VFDs, at least setting the speed with a potentiometer would be basically conceivable.

As you can see, there are many options for taking Spindle / VFD into account on the control panel, but it is not trivial which one is feasible, necessary, or desired.